In the process of cutting the stone with the diamond segment, due to the violent friction between the diamond and the stone, in this process, the stone powder is continuously peeled off from the stone, and the stone powder is quickly fused with the cooling water used for cutting, and the muddy stone powder water is continuously washed by the subsequent muddy stone powder water, and eventually most of it will flow to the drainage channel and enter the water circulation system of the mine or stone factory.

The above parts are the basically problems that stone cutting places have to face, but if the design of the segment is unreasonable, or there is a problem with the amount of water and the angle during the processing, it will lead to chip removal problems. So what exactly is the chip evacuation problem? The following is a detailed introduction to the common chip removal problems in stone factories:

1: When cutting granite, the quartz particles in the granite are relatively large, it is very likely that the segment did not cut these hard quartz, and because the edge of the quartz has been cut, the final quartz is in the shape of small pieces. Or the shape of the coarse particles falls to the bottom of the cutting surface, so that when the segment is cutting the stone below, the quartz that has been peeled off will be cut twice. If this continues for a long time, the life of the segment will be greatly shortened, the efficiency is also reduced obviously.

2: There are other possibilities for chip removal. For example, the peeled stone particles will splash out, and some will be directly stuck on the saw blade base or the side of the segment. When the segment is cutting, the cutting surface will be scratched. If there is some damage, some stone chips will directly make a deep scratch on the base of the saw blade.

3: The problem of chip removal will also affect the cooling problem of the segment. Due to excessive stone chips, the water passage of the segment is blocked, and the water cannot cool the segment well. The temperature of the segment increases slowly, and finally due to the temperature is too high, unstable performance will occur.

4: There is also the worst case is that the diamond falls off directly and gets stuck in the gap of the bottom stone, which will not only cause the segment to be consumed very quickly, but also easily drop the segment.

So in general, the chip removal work of the diamond segment is very important, so how can we avoid these problems? The main suggestions are as follows:

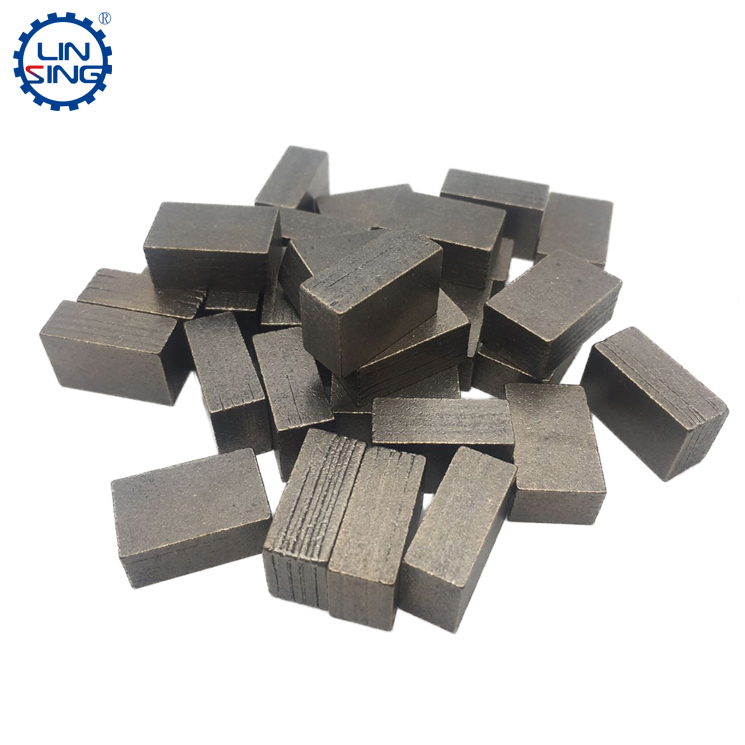

1: The design of the segment should be more reasonable. During the design process of the segment, the segment with layer structure should be adopted as much as possible. In this way, the water channel can be more dispersed, and because the more layers of the segment, the more sharper the segment is, so in order to avoid the problem of chip removal of the diamond segment, then increase the number of layers of the segment as much as possible.

2: The carcass should not be too soft or too hard. In many cases, the chip removal of the segment is caused by the too soft segment. Because of the too soft segment, the diamond will fall off without fully forming a tail, and cannot be formed. Another problem caused by the waterway is that the segment is too hard and the diamonds are consumed too fast to form a waterway, thus directly compacting the stone powder. So the carcass design is very important.

3: Control the amount of cooling water, neither too little nor too much, too little will cause too many stone chips, too much will easily polish the segment.

4: Finally, reduce the speed of the diamond segment appropriately, which can reduce the amount of stone powder, thereby reducing the difficulty of chip removal.

Principle of chip removal of diamond segment

Publish date:2022-07-14 15:25:37 Article From:Linsing Diamond Tools Clicks: