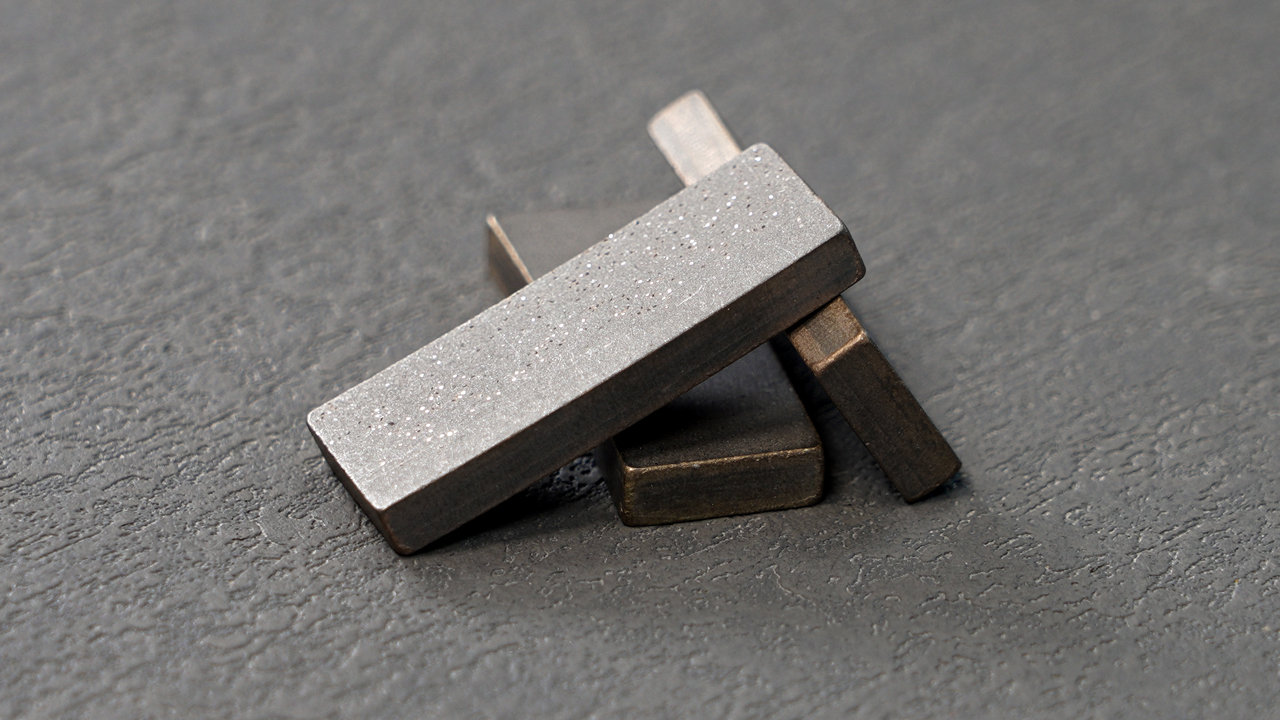

Diamond segments are usually used on cutting tools, such as diamond saw blades and gang saw blades. The use of these tools usually includes the following steps:

1. First of all, choose the appropriate type and specification of the diamond segment, and choose according to different materials and processing requirements.

2. When installing the diamond segment, pay attention to the installation method and tightness of the diamond segment to ensure the stability and precision of the diamond segment.

3. Adjust processing parameters, including cutting speed, feed rate, cutting depth and other parameters, and select according to processing materials and requirements to achieve the best processing effect.

4. During the processing, it is necessary to clean up the chips and liquid coolant in the diamond segment and the processing area in time to prevent the increase of cutting resistance and damage to the diamond segment.

5. After processing, the diamond segment should be disassembled and cleaned in time to prolong the service life of the diamond segment.

6. Finally, pay attention to safety issues and use personal protective equipment to prevent accidents.

Specific operations and adjustments are required according to the specific processing task and the type of diamond segment.

In terms of working principle, the diamond segment mainly cuts through friction and wear. Specifically, when the diamond segment is in contact with the object to be cut, due to the extremely high hardness and wear resistance of diamond, it can rub and wear the surface of the object to be cut, so as to achieve the purpose of cutting.

During the cutting process, it is usually necessary to add a certain amount of cooling liquid, such as water, oil, etc., between the diamond segment and the object to be cut, so as to prevent the excessive heat generated during the cutting process from increasing the wear of the diamond segment. In addition, in order to ensure cutting quality and efficiency, it is necessary to select appropriate cutting parameters, such as cutting speed, diamond segment rotation speed, feed speed, etc., according to the hardness and nature of the object to be cut.

In addition to cutting stone, the diamond segment is also usually used for cutting blades. Diamond segments can be used for grinding and polishing stone surfaces, and are usually installed on tools such as stone cutters or hand-held angle grinders. The specific usage method is as follows:

1. Check whether the diamond segment has been installed on the tool correctly, and confirm whether the diamond segment rotates smoothly.

2. In order to avoid the diamond segment being damaged by overheating, it is necessary to soak the diamond segment in water before use.

3. Before starting to use, it is necessary to roughly cut the stone to be polished to smooth the surface of the stone.

4. Turn on the tool, move the tool according to the required angle and direction, let the diamond segment touch the stone surface, and start grinding.

5. When grinding, pay attention to maintaining the vertical angle between the diamond segment and the stone surface, and do not apply excessive force, otherwise it may cause the diamond segment to wear too quickly.

6. With the increase of use time, the diamond segment may wear out and become blunt, and a new diamond segment needs to be replaced in time.

7. It is necessary to keep the diamond segment clean and lubricated during use. You can spray some stone polishing fluid or lubricant on the diamond segment to reduce wear and improve cutting efficiency.

It should be noted that due to the large amount of stone chips and dust generated during diamond cutting, it is necessary to wear protective equipment such as protective glasses and masks to avoid any impact on health.