The production process of diamond wire saw includes the following key steps:

Preparation of diamond beads: The production process of diamond beads mainly includes the following key steps:

Selection of diamond particles: Firstly, it is necessary to select suitable diamond particles as raw materials. Diamond grains are usually made from natural diamond or synthetic diamond. According to the required cutting or grinding requirements, choose the appropriate size and shape of diamond particles.

Pretreatment and filter: Diamond particles undergo pretreatment, such as washing and decontamination, to ensure the purity and quality of the particles. Then, through the screening process, the diamond particles are classified according to the particle size for subsequent use.

Mixing and formulation: Mix the screened diamond particles with binders, metal powders and other auxiliary materials. The choice of bonding agent is based on specific requirements. Common bonding agents include metal bonding agents (such as nickel, cobalt, iron, etc.) and vitrified bonding agents. The ratio of the formula is adjusted according to different applications and requirements.

Pressing and Forming: The mixture is placed in a mold and subjected to high-pressure compression to form it. The high pressure enables the diamond grains and binder to bond tightly to form a strong structure. In the pressing process, two stages of pre-pressing and final pressing are usually used to ensure uniform compactness and density.

Sintering: The pressed diamond beads are solidified through a high temperature and high pressure sintering process. The selection of sintering temperature and pressure depends on the specific material and process requirements. During the sintering process, the bonding agent and the diamond particles react chemically to form a firm bond, which makes the diamond beads have high hardness and wear resistance.

Machining and Trimming: The sintered diamond beads are machined and trimmed to ensure their size, shape and surface quality are as required. This includes processes such as cutting, grinding, and polishing to achieve a flat, smooth surface and consistent dimensions.

Quality inspection and screening: Quality inspection of the produced diamond beads, including visual inspection, size measurement, hardness test, etc.

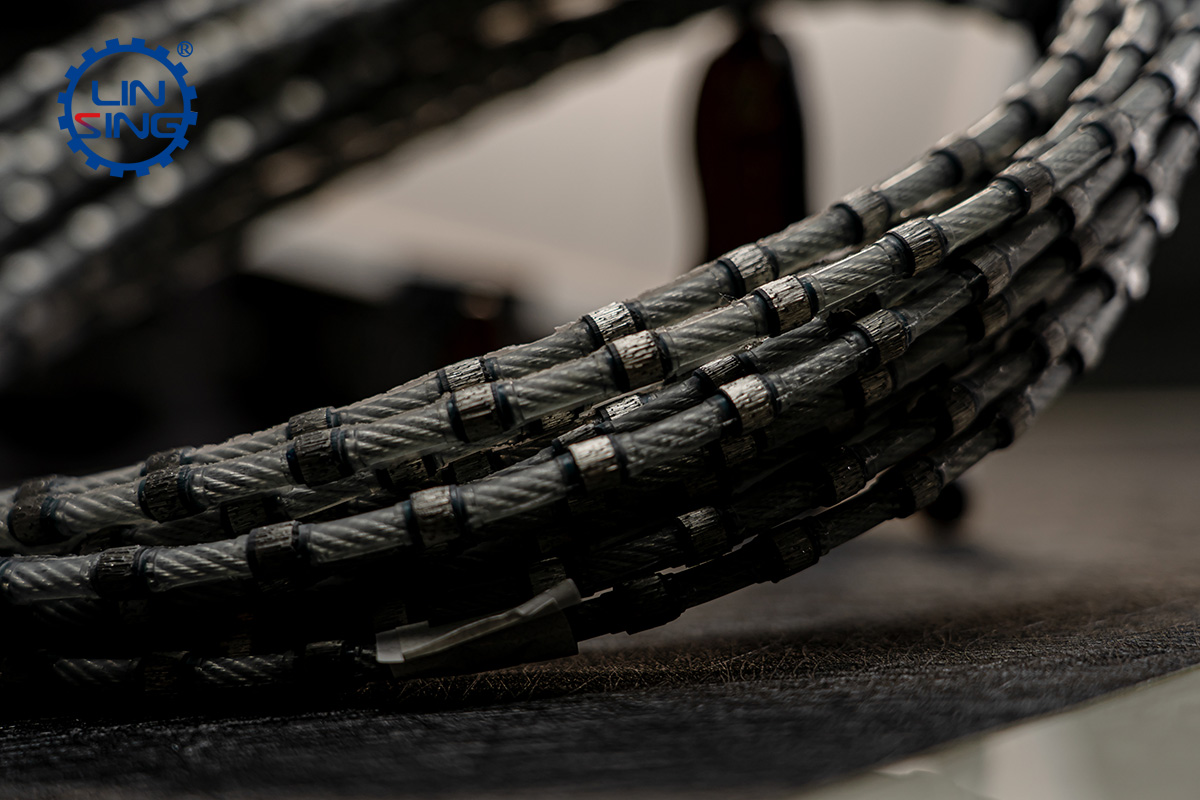

Prepare the wire rope: select the appropriate wire rope as the cutting material, and determine the diameter and structure of the wire rope as required. The wire rope should have sufficient strength and flexibility to withstand the tension and bending during the cutting process.

Fixing diamond beads: Fix the diamond beads evenly on the wire rope, usually by welding or using a special fixative. The welding method can use techniques such as electric welding or laser welding to ensure that the diamond beads are firmly fixed on the wire rope.

Adjust the structure of the wire saw: According to the actual needs, adjust the spacing and arrangement of the diamond beads on the wire rope to meet the cutting requirements. The appropriate bead spacing and density can be selected according to different cutting materials and cutting tasks.

Inspection and quality control: inspect the diamond wire saw produced, including visual inspection, size measurement, cutting performance test, etc., to ensure that the product quality meets the requirements.

Packaging and delivery: The qualified diamond wire saw is packaged, generally in a moisture-proof and shock-proof package to ensure that the product is not damaged during transportation and storage. The products are then shipped out of the factory, ready for delivery to customers or distributors.

The above is the general production process of diamond wire saw, and the specific production process may vary according to different manufacturers and product characteristics.