Concrete grinding is a very popular method of ground treatment in recent years. The most commonly used are epoxy floors and self-leveling floors, and the color is mixed into the concrete. Finally the ground is polished, which will form a surface that is not easy to fade or change color. The environmentally friendly concrete floor cost is low, suitable for factories, underground garages, etc.

Why use diamond segment for concrete grinding?

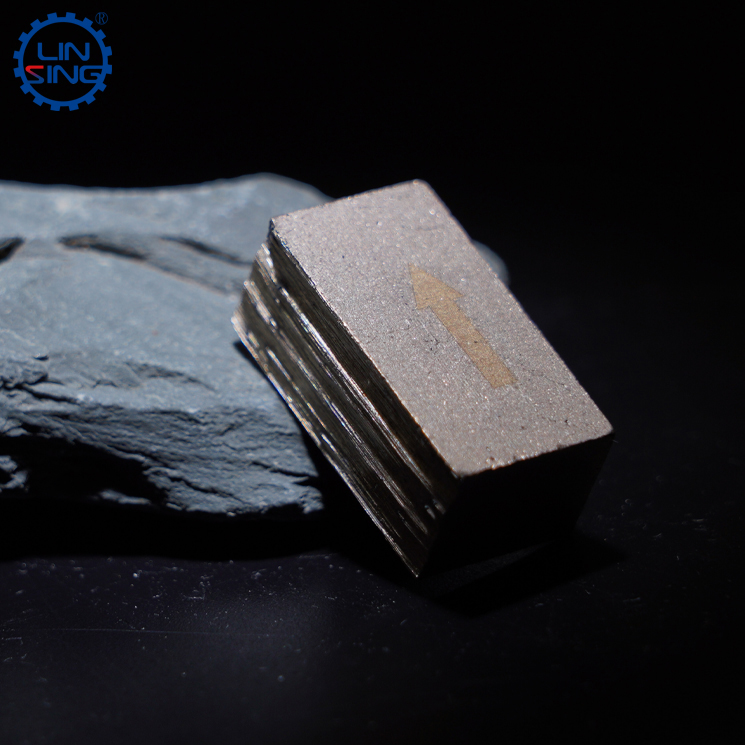

There is diamond in the diamond segment, and diamond is the hardest substance. During the grinding process, the diamond in the diamond segment continuously grinds the concrete floor. If the ground is uneven , or there are uneven places on the concrete floor, these places will be quickly ground and leveled, and eventually a ground with high flatness will be formed as the standard. However, it does not grind all the ground.

Why use diamond segments for grinding? Because the size of the diamond segments are relatively small, and the grinding effect will be higher during operation. If a larger size segments are used, the mechanical power will be larger, which will waste electricity. In addition, the type of such large segments Higher, the mechanical difficulty is increased, and the portability is not strong. Therefore, using the diamond segments for grinding is relatively labor-saving and hassle-free, and can also be well guaranteed in terms of efficiency.

So how do you grind concrete with a diamond segments?

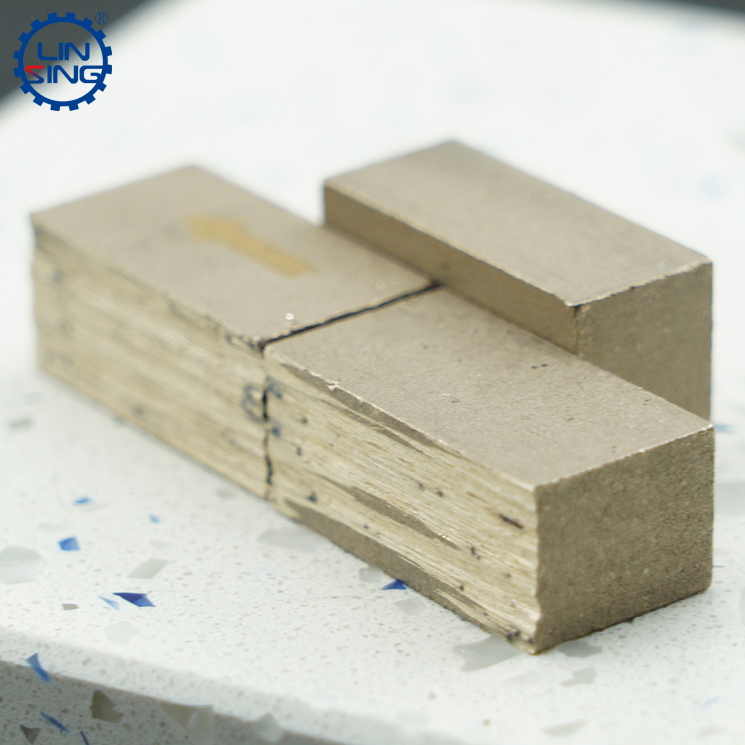

The diamond segments generally need to be fixed on the segment. Because sometimes there may be no water or less coolant in the process of concrete grinding It is recommended to use laser welding to weld the concrete segment. It is obvious large part of the floor welding blocks are welded by high-frequency welding machines. During the welding process, copper electrodes or silver-copper electrodes are used to heat the diamond segments and the electrode until the finally melted electrode is cooled. Welded frankfurt shape or disc-shaped grinding disc will be attached to the concrete floor grinder.

During the grinding process, the concrete floor grinder uses the diamond segment installed below to grind it. In the process of moving the grinder, if there is a difference in the mechanical level, or some obviously uneven ground, it needs to be ground. It is best to choose the processing mode with water, which will reduce the generation of a lot of dust, and the grinding effect and grinding efficiency are also much higher than that of the waterless grinding environment.

Are there other products other than diamond segments that can be used to grind concrete?

There is also a concrete grinding product of PDC composite sheet. This product is very expensive, but the advantage of this product has long lifespan and is suitable for dry grinding. In the process of processing, it will not be affected by the high hardness of the concrete.

If the concrete is polished, it is better to use a resin grinding disc or grinding wheel to grind the concrete floor. Because the diamond particle size of concrete grinding is relatively large. After polishing by resin grinding disc, this situation will be significantly improved.

At present, resin-metal hybrid grinding discs are also popular, which can take into account the rough grinding and fine grinding of concrete, and have the potential to become the mainstream concrete abrasive tool in the future.

There is currently no specific size for the shape of the concrete grinding diamond segments, so most manufacturers will customize it according to the requirements of customers. The main reason is that the production labels of concrete around the world are different from some materials, and it is difficult to make a concrete judgment on the characteristics of local concrete in the first place. Only through long-term cooperation can we finally formulate diamond segments suitable for local concrete formulations.