Diamond gang saw segment is mainly used in gang saw machine. Through high frequency welding process, the segment is welded to the bottom of gang saw blade (also called cutting blade), and the cutting of stone is completed by mechanical back and forth sawing. Because the blade of gang saw is relatively soft, if cutting hard stone, there will be deflection, so gang saw segment is almost used for cutting marble, rarely used for cutting hard granite.

There are currently three shapes of gang saw segments on the market, and this article will introduce them one by one:

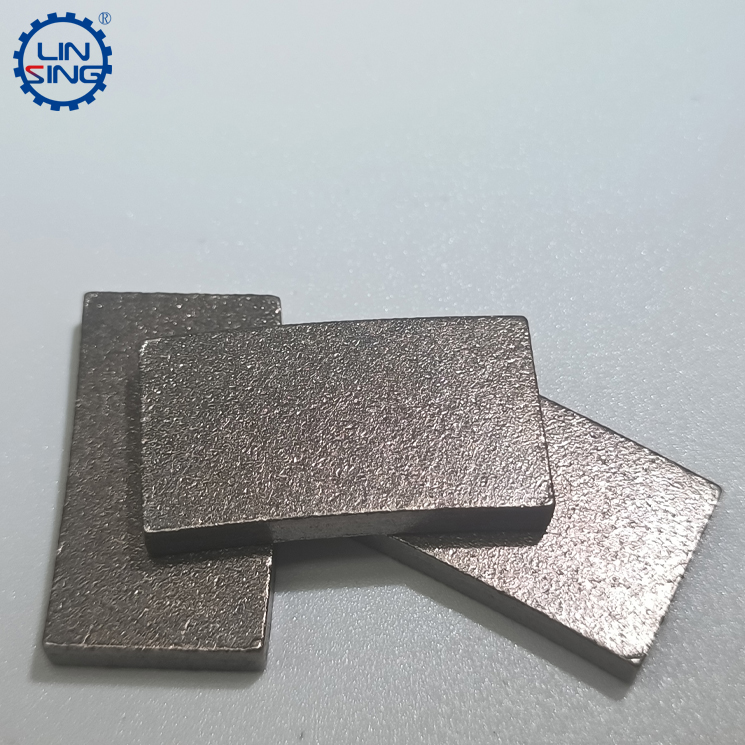

The first type: parallel-shaped gang saw. This gang saw segment adopts a cube design. From the side, the segment presents a trapezoid with a wide upper side and a narrow bottom. From the front, the entire segment has a square appearance. In general, The overall parallel segment presents an inverted trapezoidal appearance design. The advantage of this kind of segment is that the parallel segment has a high sharpness during the initial cutting process. Because the cutting edge is narrow and small, the cutting edge is convenient. And during the gang saw round-trip process, the consumption is relatively fixed, and the possibility of segment eccentric wear is small.

The second type: Isosceles trapezoidal gang saw. This gang saw segment is in the shape of an isosceles trapezoid when viewed from the front. When viewed from the side, it is also a shape with a wide top and a narrow bottom. In general, the segment presents a kind of top. The appearance is wide and narrow at the bottom, short at the top and long at the bottom. In the process of processing this kind of segment, because the upper part of the segment is short, the upper part can be quickly ground, and it is also easy to sharpen the edge. When the segment is ground to the bottom, the segment becomes slender, which also makes The segment takes into account the life, especially the processing of the stone in the second half, which is more stable.

The third type: right-angle trapezoidal gang saw. In the process of processing stone, the trapezoidal surface is used for rapid cutting, and the right-angled surface is used to crush the hard part of the stone. For those with higher hardness Stone also has cutting ability, so it can also be used for cutting soft granite. This segment is characterized by strong versatility, strong applicability, and sharpness, which is suitable for the later improvement of gang saw segment.

In the process of stone processing, in addition to the shape factor, the gang saw segment has differences in segment specifications. The segment specifications mainly refer to the design of the length, width and height of the gang saw segment. We will explain these three aspects separately below.

The length of the gang saw segment reflects the life of the segment to a large extent. The longer the segment, the more the cutting part, so in the process of cutting the stone, the smaller the pressure, the slower the cutting, and the longer the life, in order to ensure that the segment has more For good sharpness and longevity, people use a segment length of 20mm as the standard.

The width of the gang saw segment is determined by the thickness of the gang saw substrate. The thicker the gang saw segment, the thicker the thickness of the gang saw segment is required, otherwise the saw blade is prone to wear, so the thickness of the gang saw segment should be slightly wider The thickness of the saw blade.

The height of the gang saw segment is a way to increase the cutting life of the segment. Usually, people use 8mm and 10mm as the height. If you continue to increase it, the segment will experience eccentric wear. If the height is too low, the segment life will not reach To meet the requirements, resulting in high stone cutting costs and welding costs, thereby increasing production costs.

Summary of diamond gang saw segment shapes and specifications

Publish date:2022-07-07 14:51:41 Article From:Linsing Diamond Tools Clicks: