Diamond segment is an accessory commonly used in stone processing tools. It cannot be used independently. It often needs to be used with a substrate. So what tools can Linxing's diamond segment be used for? 1. Diamond saw blades, here specifically refers to diamond cold-pressed, hot-pressed sintered welded saw blades, or laser welded saw blades. The size of diamond saw blades is different according to the diameter range, the diameter is 105-4500mm, and the diameter range of 105-230mm diamond discs are often cold-pressed discs, and the discss used are cold-pressed sintered discs, which are integrally processed and formed through a medium-sized stove. Most of the 250-850mm are medium-diameter saw blades, which are mostly used for edge cutting and small blocks. Saw blades with a diameter of 900-3500mm are widely used for cutting medium and large blocks, or trimming, or cutting, or for cutting large plates. There is also a larger size saw blade, with a diameter range of more than 3500mm, most of which are used in granite mining, and are used in mining circular saws.

1. Diamond saw blades, here specifically refers to diamond cold-pressed, hot-pressed sintered welded saw blades, or laser welded saw blades. The size of diamond saw blades is different according to the diameter range, the diameter is 105-4500mm, and the diameter range of 105-230mm diamond discs are often cold-pressed discs, and the discss used are cold-pressed sintered discs, which are integrally processed and formed through a medium-sized stove. Most of the 250-850mm are medium-diameter saw blades, which are mostly used for edge cutting and small blocks. Saw blades with a diameter of 900-3500mm are widely used for cutting medium and large blocks, or trimming, or cutting, or for cutting large plates. There is also a larger size saw blade, with a diameter range of more than 3500mm, most of which are used in granite mining, and are used in mining circular saws.

The above-mentioned saw blades all require diamond segments. These saw blades complete the cutting of stone through the consumption of the sawtooth part of the diamond segments, which are the tool with the largest consumption of diamond segments.

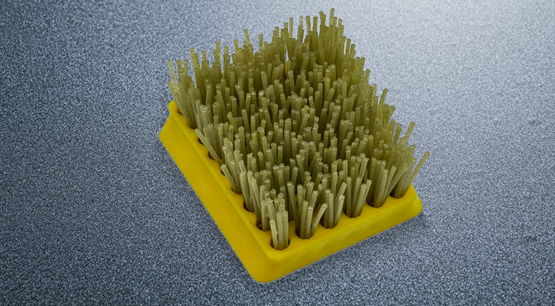

2. Grinding disc, grinding block diamond segment or the grinding disc segment is mainly diamond tool for grinding the surface of stone or concrete, mainly for grinding, correcting, removing rough grinding processes such as stone surface burrs. Such as common metal grinding discs, this grinding discs are widely used in granite grinding. As shown in the figure, this kind of grinding discs use 50#, 100#, 200# coarse-grained diamonds for rapid processing of stone surfaces.

In addition to this type of grinding disc segment, Frankfurt abrasives for rough grinding of marble are also relatively common. This Frankfurt segment is suitable for rough grinding of marble and concrete surfaces. Different from granite, the shape of the diamond segment of this kind of marble grinding disc has more changes, and it can be used with materials such as PDC or PCD, which can effectively increase the life of grinding.

Besides small diamond segmentss, the diamond segment can also be made larger, such as diamond fickert, which is a combination of one or several large diamond segments. This tool is widely used in granite processing. This product requires adapt suitable machinery (fickert type fully-antomatic polishing machine).

3. Grinding wheel diamond segment. Stone grinding wheel is a commonly used material in the process of special-shaped stone products or edge processing, such as commonly used diamond bowl grinding, CNC grinding wheel, router bit, CNC stubbing wheel, etc., are very commonly used stone finishing tools, these grinding wheels all require diamond segments.

In addition to the shaping function, grinding wheels can also be used for calibration work, such as satellite abrasive, which use larger particles for quick calibration of stone materials.

4. Drill bits. At present, diamond bits are widely used for hollow drills, especially wall drills, stone drills and drill bits for water well drilling. They are all made of diamond segments combined with drill bases for welding. 5. Milling bits, the diamond bit can also be welded on the milling bit, which can be used for sink processing.

5. Milling bits, the diamond bit can also be welded on the milling bit, which can be used for sink processing.

6. The current application of diamond segment is mainly used for cutting, grinding, drilling and other processes of hard materials. With the development of diamond segment technology and the diversification of shapes, it is believed that there will be more industries and applications to be developed in the future.

Summary of linsing diamond segment tools

Publish date:2022-12-13 11:00:05 Article From:LINSING diamond tools Clicks:

Diamond Segment For Gang Saw

Diamond Segment For Multi-Saw Blade

Stone Grinding Brushes

CNC Profiling Wheel

Diamond Core Drill Bit