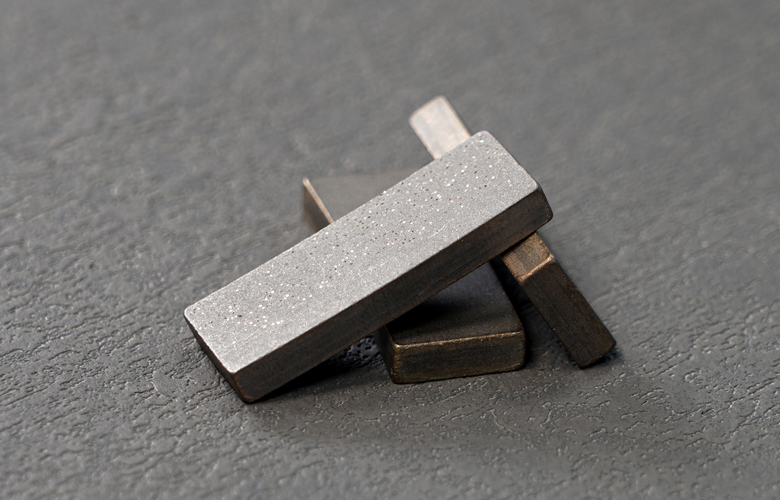

Diamond segment often have the following problems. Let's take a look at the segment in the picture below.

We can clearly see that the segment on the left is high on one side and low on the other, while the segment on the right is in a normal cutting state. The shape of the left segment is especially common on quarry segment. There are two main problems with this reason: The first cutting depth is too deep. When the cutting depth of the saw blade is too deep, the segment at the front end of the saw blade is quickly consumed, But the front end of the segment has already finished cutting, the rear end does not undertake the cutting work. this causes the segment to appear such a situation where one side is high and the other is low (the entry cutting edge is low, and the exit cutting edge is high. ); The second reason is that the blank blade of the saw blade is too soft. When the saw blade is lowered, the blade naturally curls, causing the front end to be stressed while the back end is not. This uneven force will also directly cause the segment to appear high on one side and low on the other side.

In another case, let's look at the picture below.

What we see is that the left segment belongs to the normal consumption state, and the right segment has serious unilateral wear. The occurrence of this situation will reduce the life of the segment by about 10-20%, there are three main reasons for this situation. The first point: the segment is not flat during the welding process. This situation is relatively rare in high-frequency welding, but it occurs from time to time in the flame welding process. The second point: the deformation of the saw blade causes the cutting angle deviation problem in the cutting process. The third point: During the mixing process, the middle and edge materials are not separately blended, causing the middle and edge materials to be too close, and the abrasiveness of the rock is strong, causing one side of the edge material to be quickly worn.

There is also a more common situation, mainly in sandstone segment.

In this case, the cutting layer in the middle is recessed too much, but the edge material is consumed slowly, and a groove is formed. This problem is mainly caused by the fact that the materials of the segment in the middle and the edge material are not separately adjusted, and the treatment method is also very simple. Through testing, increase the wear resistance and hardness of the middle carcass components, or appropriately reduce the wear resistance and hardness of the side material on both sides, and the diamond segment can be achieved without grooves.

In general, the diamond segment will have various problems during the cutting process. Others such as the falling of the segment, the lack of sharpness of the segment, the cut stone slabs of the segment often appear chipping and other situations can all be solved. If you have any questions you don't understand, you can consult Jiangxi Lin sing Diamond Tools Co., Ltd. We have been specialized in manufacturing and researching diamond segment products for nearly 20 years, which can solve most of the cutting and grinding problems of diamond segment.