Diamond saw blades are essential tools in various cutting and grinding applications, from construction to industrial manufacturing. Selecting the right diamond saw blade is crucial for achieving efficient and precise results. This article delves into the key factors to consider when choosing a diamond saw blade and highlights the importance of making an informed decision to optimize cutting and grinding processes.

1. Material Type: The first and foremost consideration when choosing a diamond saw blade is the type of material you intend to cut or grind. Diamond saw blades are designed with specific bond types and diamond grit sizes tailored for different materials such as concrete, asphalt, stone, metal, ceramic, and more. Selecting the appropriate blade for your material ensures optimal performance and longevity.

2. Working Conditions: Environmental factors play a significant role in blade selection. Consider the working conditions, including temperature, humidity, and exposure to water or abrasive materials. Certain blades are better suited for wet cutting, while others excel in dry cutting applications. Adverse conditions can affect blade wear and performance, so choosing the right blade for the environment is crucial.

3. Cutting Precision: The required precision of your cutting or grinding job is another key factor. Different blades offer varying levels of precision, from standard blades for rough cutting to specialized blades for fine, detailed work. Understanding your project's precision needs helps you select a blade that delivers the desired results without compromising efficiency.

4. Cutting Depth and Width: The depth and width of the cut also influence blade selection. Blades come in various sizes, and choosing the right diameter and segment height ensures that you achieve the desired cut dimensions. Using an appropriately sized blade prevents overloading and extends its lifespan.

5. Frequency of Use: Consider how frequently you will be using the diamond saw blade. For occasional or light use, a standard-quality blade may suffice. However, if your project involves heavy, continuous use, investing in a high-quality, long-lasting blade can save time and money in the long run.

6. Budget: Budget constraints are a practical consideration. While high-quality blades tend to be more expensive upfront, they often offer better performance and longevity, reducing replacement costs in the future. Balancing your budget with your project requirements is essential for cost-effective results.

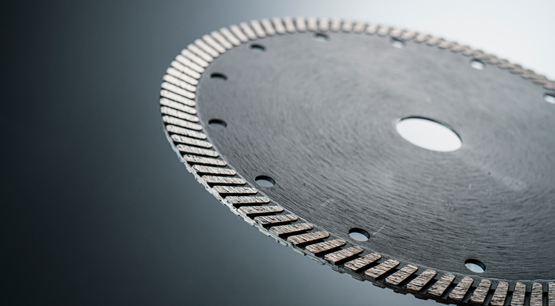

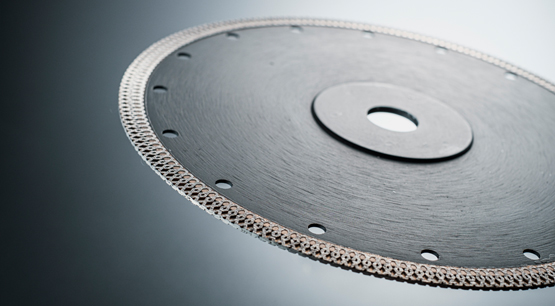

7. Blade Type: Diamond saw blades come in various types, including continuous rim blades, segmented blades, turbo blades, and more. Each type has specific characteristics, making them suitable for different applications. Understanding the advantages and limitations of each blade type helps in making an informed choice.

8. Diamond Grit Size: Diamond grit size influences the aggressiveness and smoothness of the cut. Coarser grits provide faster cutting but may result in a rougher finish, while finer grits offer smoother cuts at a slower pace. Matching the diamond grit size to your project's finish requirements is crucial.

9. Arbor Size: Ensure that the blade's arbor size matches your equipment's arbor or spindle size. Using the correct arbor size prevents compatibility issues and ensures safe operation.

10. Safety Measures: Lastly, prioritize safety when selecting a diamond saw blade. Follow manufacturer recommendations for safety equipment, such as goggles, gloves, and dust masks. Additionally, ensure that your equipment is in good working condition to prevent accidents.

In conclusion, choosing the right diamond saw blade involves a thoughtful assessment of material type, working conditions, cutting precision, depth and width requirements, frequency of use, budget constraints, blade type, diamond grit size, arbor size, and safety considerations. By carefully evaluating these factors, you can select the ideal blade for your specific project and achieve efficient, precise, and safe cutting or grinding results.

How to Choose Diamond Saw Blade Correctly

Publish date:2023-10-08 16:14:33 Article From:Linsing diamond tools Clicks:

Vacuum Brazed Diamond Saw Blade

Continuous Rim Diamond Cutting Disc

Turbo Cutting Disc

X Mesh Turbo Cutting Disc

Turbo Type Protection Teeth Cutting Disc

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- Hot pressing sintering technology of diamond segment

- What should do if the segment is moved grinding during the cutting process?

- Sintering process of Linxing diamond segments

- Important notice! 2020 Xiamen International Stone Exhibition will be postponed to October 27-30!