The shape of the diamond segment is determined by its cutting object and the two parts of the stone cutting process. The cutting objects are divided into marble, granite, sandstone, volcanic rock, limestone, quartz stone, even ceramic tile, reinforced concrete, etc. The stone cutting process is divided into mining, block cutting, block breaking, edge cutting and so on. Below we mainly learn more about the shapes and types of diamond segments used for marble and granite cutting.

The shape of the marble cutting segment is as follows:

There are two main shapes of the marble block cutting segment and the cutting head: M-type block cutting segment (this kind of segment is more conducive to cutting edge), flat block cutting segment (this kind of cutting segment is more edging) Evenly, the life is slightly longer than the M-type segment.

The shape of the cutting segment of the marble gang saw is as follows:

There are three main types of marble gang saw segments: parallel segments, isosceles trapezoid cutter heads and right-angled trapezoid segments. The front section of the segment presents these three different shapes, but in fact, the cross section of the segment is also presented. The shape of the isosceles trapezoid is mainly because the segment is wide in the upper part and narrow in the lower part, which protects the substrate and facilitates chip removal.

The shape of the marble slab cutting segment is as follows:

This marble cutter head is mainly used for circular saw blades with a diameter of less than or equal to 600mm. The main shape of the segment is R type, that is, a fan shape. There is also a type of segment that is different from the fan shape and is called an Arc segment. The difference between the two is that the spacing between the fan-shaped segments is smaller, while the arc-shaped segment is welded to the circular saw blade with a larger spacing. In terms of specific work, the fan-shaped segment has better continuity, and chipping is not easy to occur during the cutting process; while the arc-shaped segment has better sharpness and higher cutting efficiency. However, it is prone to unstable cutting and poor cutting quality. In particular, expensive stone is generally cut with a fan-shaped segment, and the length of the segment is deliberately lengthened during the design process of the segment, so that the segment is closely connected with the segment. This kind of segment is also widely welded in the blank blade of J-slot saw blade. In this way, this saw blade is also called a J-slot saw blade.

The shape of the granite cutting segment is as follows:

There are three main shapes of granite mining segments: M-type segment (this kind of segment is the most commonly used and is easy to opening), K-type mining segment (this kind of segment is relatively rare at present, the advantage is that the diamond opening is strong, but the disadvantage is that the segment is prone to unevenness, resulting in insufficient use of the segment). Round mine segment (The cutting process of this segment is very smooth, the disadvantage is that the round iron sheet increases the processing cost, and the diamond opening will be slow.

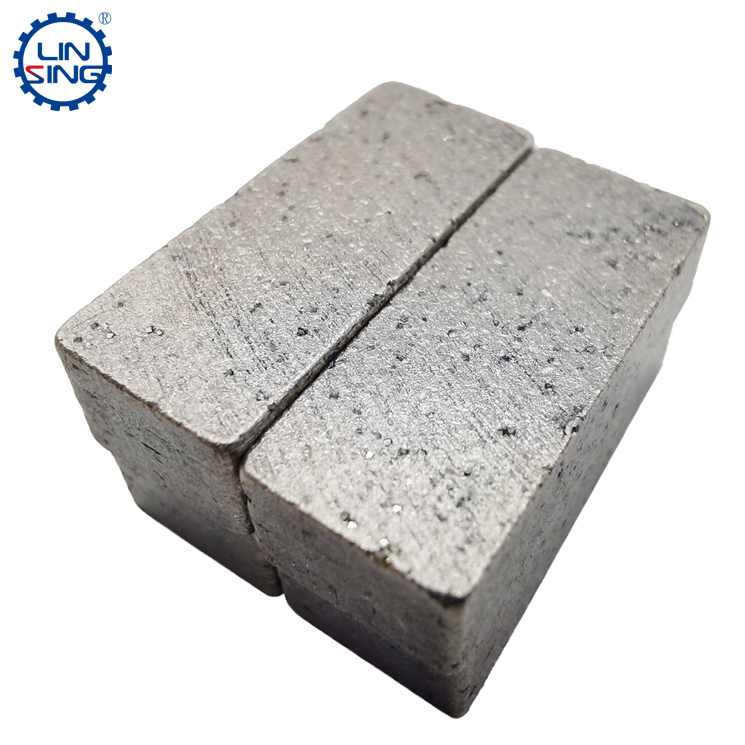

There are two main shapes of granite block cutting and split: M-type block cutting segment (this kind of segment is good for edge broken, currently the most commonly used granite cutting), and the other is a flat block cutting segment (this type of head is mainly used for soft stone cutting.

The shape of the granite slab cutting segment is as follows:

Granite edging cutting segment come in a wide variety of shapes:

1: M type: This kind of segment has high sharpness, but has a short life.

2: Arc: This kind of segment has moderate sharpness and moderate lifespan.

3: Fan shape: This kind of segment has low sharpness, but good cutting stability.

4: Short-R segment : This kind of segment has high sharpness and long life, but it is difficult to weld.

5: V type: This kind of segment has high sharpness, poor service life and low welding difficulty.

6: Unilateral turbine: This kind of segment has extremely high sharpness and good continuity, but the cutting life is short.

In general, there are many shapes of diamond segments, which must be determined according to the characteristic processing objects and occasions

Does the diamond segment has how many shape?

Publish date:2022-07-13 17:51:20 Article From:Linsing Diamond Tools Clicks: