The segments running away is a kind of cutting performance that often appears in the stone cutting process. The main performance is the following three situations: 1: Deviation; The stone cutting line deviates, such as cutting a straight line, but in the actual cutting process, the cutting deviation occurs, the cutting line is not straight, but some distortions, or the shape of corrugated lines. When appears incision, it means that the stone has run away.

1: Deviation; The stone cutting line deviates, such as cutting a straight line, but in the actual cutting process, the cutting deviation occurs, the cutting line is not straight, but some distortions, or the shape of corrugated lines. When appears incision, it means that the stone has run away.

2: Running skew; During the stone cutting process, the original vertical line is finally cut into various uneven incisions, the main performance is that the stone cutting surface is inclined and uneven.

3: Deviating; During the cutting process of the stone, the edge of the stone cut by the saw blade is obviously distorted. Unlike the deviation, most of this situation is caused by manual irregular operations. The stone that is almost crooked is almost can’t repair.

The segment running away directly causes the stone to be unusable, and the damage to the saw blade is relatively large, so what is the reason for the segments running away? There are mainly four common reasons. We can learn together as below:

1). The substrate thickness is not standard, and the flatness error is ≥±0.1. Most of the segment running situations are caused by this reason, especially with the development of modern stone processing technology, the quality of machinery and tools has been greatly improved, but in terms of substrate production, errors will cause saw blades to rotate incorrectly. In this case, when the saw blade cuts stone, especially when the fatigue value of the matrix reaches a critical value when the saw blade is overloaded, this flatness error will cause the saw blade to shift or even swing , under such circumstances, it is natural that the situation of segments running away occurs.

However, the solution to this situation is also very simple. We can find a saw blade substrate manufacturer with higher flatness, and choose a substrate with higher precision, less error, and better performance to completely avoid such problems.

2). The end jump of the base body (end jump, the top of the saw blade, that is, the size of the swing of the segment to the left and right ends when the saw blade rotates) exceeds the standard range, and the end jump range of a 350/400mm diameter granite saw blade should be ≤0.3mm, and the end jump range of other large-sized saw blades should also be kept in a lower range. When the diamond saw blade leaves the factory, it will detect the static end jump and the dynamic end jump. The smaller the range of the end jump, the less likely the diamond saw blade will run away during the cutting process, and there will be no more serious problems. Conversely, if the end jump value of the saw blade is large, then the probability of running the knife will be greater when such a saw blade cuts stone.

Generally speaking, the end jump test is a must for saw blades to be tested when they leave the factory. Choosing a large diamond saw blade manufacturer can obviously avoid this problem.

3). The blade thickness is too thin and the sharpness is not too high. With the development of the stone industry and the rapid advancement of sawing technology, it is the future development trend to use more thin saw blades for stone cutting. However, when the size of the saw blade and the blade are too thin, especially the blade with insufficient sharpness. In the process of cutting stone, it is easy for the segment to run away. If the segment is too thin, the stone will wear the substrate, and the worn substrate will aggravate the thickness imbalance, and the segment will run away.

4). Following the previous point, reducing the thickness of the substrate can solve the third problem very well. However, the reduction in the thickness of the substrate brings about a reduction in the rigidity of the substrate and an increase in its flexibility. In the actual cutting process, it is easy for the saw blade to deviate. At present, it can only be solved by purchasing a matrix material with better rigidity, but the material cost of the matrix has increased significantly. In general, the idling problem of the diamond segment is mainly caused by the insufficient sharpness of the segment and the problem of the thickness of the substrate. Only by continuously improving the cutting sharpness of the segment and continuously improving the rigidity and resistance of the substrate material can solve the problem. Jiangxi Linxing Diamond Tools Co., Ltd. is a professional manufacturer of diamond segments and saw blades. After years of research, it has solved the problem of most saw blades running on the market. We look forward to our customers calling and visiting.

In general, the idling problem of the diamond segment is mainly caused by the insufficient sharpness of the segment and the problem of the thickness of the substrate. Only by continuously improving the cutting sharpness of the segment and continuously improving the rigidity and resistance of the substrate material can solve the problem. Jiangxi Linxing Diamond Tools Co., Ltd. is a professional manufacturer of diamond segments and saw blades. After years of research, it has solved the problem of most saw blades running on the market. We look forward to our customers calling and visiting.

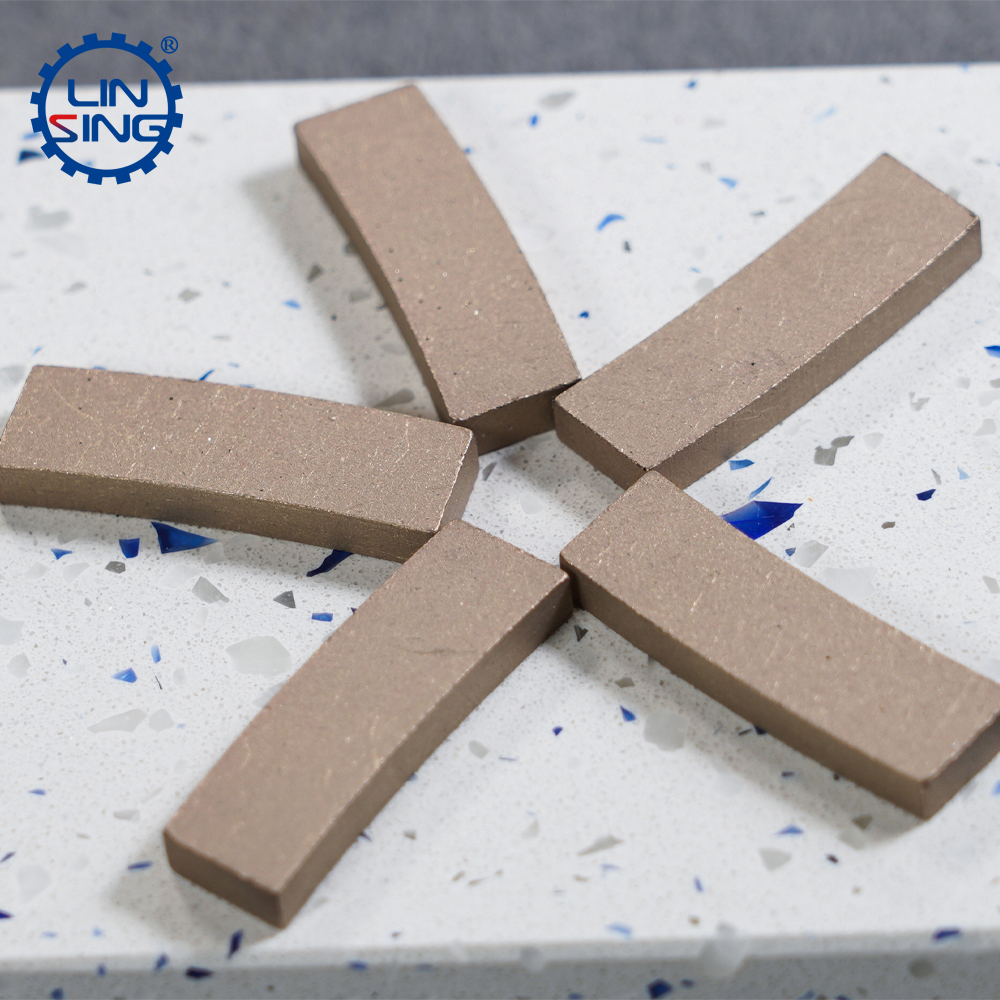

Cutting with diamond segments appears running away

Publish date:2022-12-05 13:27:30 Article From:LINSING diamond tools Clicks: