The diamond segment for stone is a tool widely used in the stone processing industry. Its main features are extremely high hardness and wear resistance, And the main feature is that it has extremely high hardness and wear resistance, and can maintain a long-term high-efficiency working state when cutting and grinding stones, while ensuring the quality and aesthetics of the stones. The characteristics of the diamond segment for stone will be described in detail below. First of all, diamond is one of the hardest substances known so far, its hardness is second only to a few substances such as cubic boron nitride and tungstate, so it has very high wear resistance. The diamond segment for stone uses diamond particles as the main abrasive. It is made by high temperature and high pressure sintering technology. It has extremely high hardness and wear resistance, and can maintain a long-term efficient working state when cutting and grinding stone.

First of all, diamond is one of the hardest substances known so far, its hardness is second only to a few substances such as cubic boron nitride and tungstate, so it has very high wear resistance. The diamond segment for stone uses diamond particles as the main abrasive. It is made by high temperature and high pressure sintering technology. It has extremely high hardness and wear resistance, and can maintain a long-term efficient working state when cutting and grinding stone.

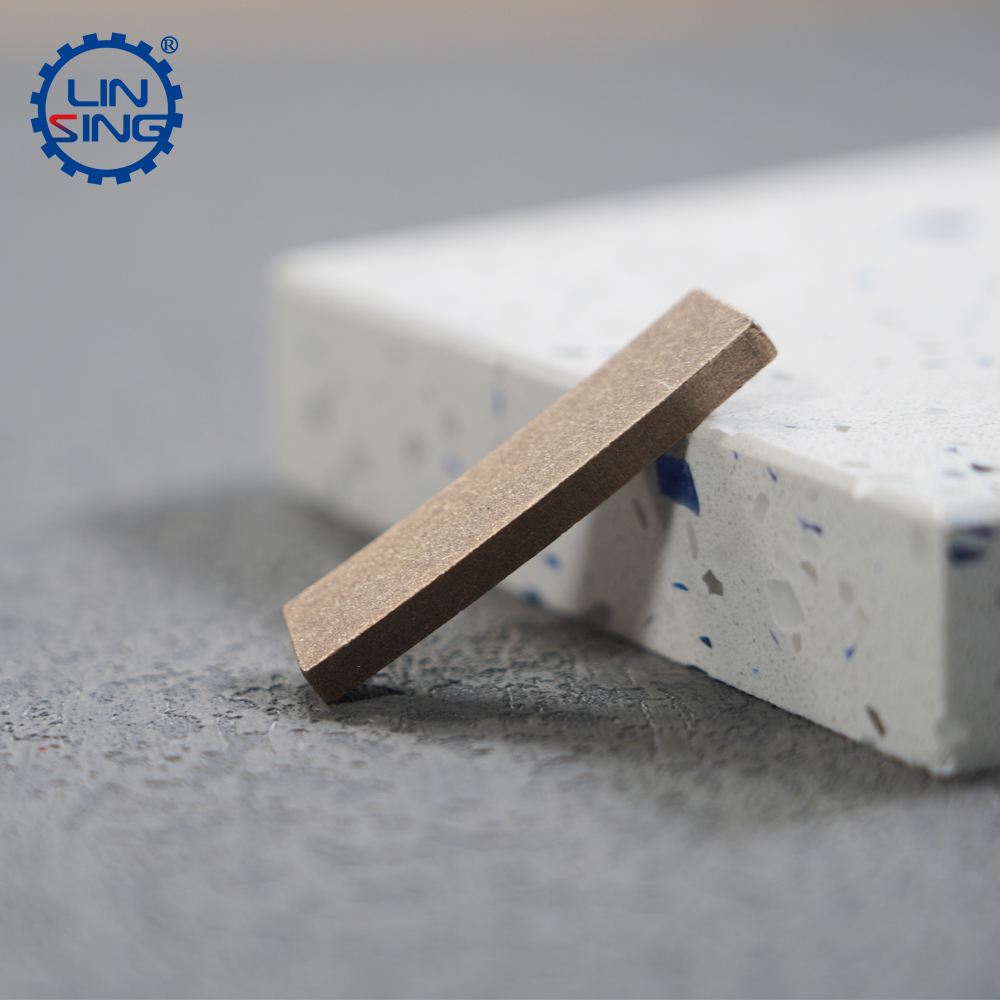

Secondly, the design of the diamond segment for stone is also very critical. Generally speaking, the blade of the diamond segment for stone is thin and long, which can be flexibly shuttled on the surface of the stone for cutting and grinding. At the same time, the design of the segment also takes into account the characteristics of the stone, so that it can cut and grinding will not generate too much heat and dust, thus ensuring the quality and aesthetics of the stone.

In addition, the selection of diamond segments for stone also needs to be considered according to the specific stone type and processing method. For different types of stones, their hardness and physical properties are different, so it is necessary to choose different types and specifications of diamond segments for cutting and grinding. At the same time, in different stone processing links, such as cutting, trimming, polishing, etc., it is also necessary to choose different diamond segments for processing to ensure the processing effect and quality of stone.

So what's the difference between a stone cutting segment and a concrete cutting segment? In fact, stone cutting segments and concrete cutting diamond segments are different in terms of physical characteristics, design and usage, and the following will compare the two.

First of all, the hardness and physical properties of stone and concrete are different. Stone is relatively hard, while concrete is relatively soft. Therefore, the stone cutting segment needs to have higher hardness and wear resistance, so as to ensure a long-term high-efficiency working state when cutting and grinding the stone surface. The concrete cutting diamond segment needs to have better cutting performance and impact resistance, so that it can be more smooth and stable when cutting on the concrete surface.

Secondly, the design of stone cutting segment and concrete cutting diamond segment is also different. The blade of the stone cutting segment is thinner and longer, which can be flexibly shuttled on the stone surface for cutting and grinding. The concrete cutting diamond segment is shorter and thicker, designed with a larger tooth pitch and tooth shape to increase the cutting area and reduce cutting resistance. In addition, the diamond segment for concrete cutting also needs to have good heat dissipation and dust-proof performance, so that excessive heat and dust will not be generated during the cutting process, which will affect the cutting effect and working environment.

Finally, stone cutting segments and concrete cutting diamond segments are used differently. The stone cutting segment generally adopts wet cutting, that is, spraying water or cooling liquid during the cutting process to reduce the temperature and reduce dust. The concrete cutting diamond segment generally adopts dry cutting, that is, it does not need to spray water or coolant during the cutting process. In addition, when cutting concrete, special attention needs to be paid to the depth and speed of the cut to avoid problems such as overcutting or cracking. In short, the diamond segment for stone has extremely high hardness and wear resistance, which can maintain a long-term efficient working state when cutting and grinding stone, and at the same time ensure the quality and aesthetics of the stone. When selecting and using diamond segments for stone, it is necessary to consider according to the specific stone type and processing method, and pay attention to the size of the segment to prevent the wrong size of the segment from causing problems in saw blade cutting.

In short, the diamond segment for stone has extremely high hardness and wear resistance, which can maintain a long-term efficient working state when cutting and grinding stone, and at the same time ensure the quality and aesthetics of the stone. When selecting and using diamond segments for stone, it is necessary to consider according to the specific stone type and processing method, and pay attention to the size of the segment to prevent the wrong size of the segment from causing problems in saw blade cutting.

What are the characteristics of diamond segment for stone?

Publish date:2023-03-13 08:39:00 Article From:Linsing diamond tools Clicks: