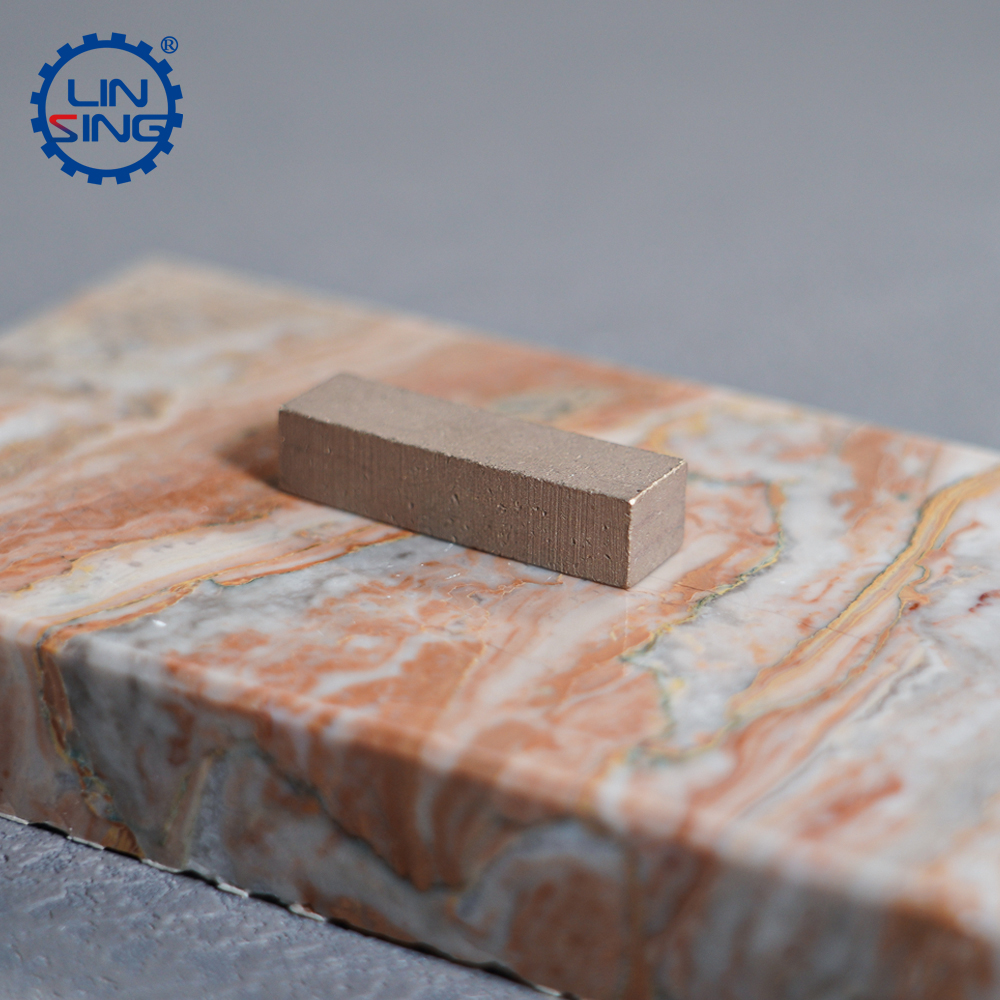

In the early years, due to the relatively backward welding technology, diamond saw blades were usually completed by hand-welding the segment. This is a traditional way of welding the segment. Although compared with modern automation equipment, manual welding it has low efficiency and insufficient stability, but it is still widely used in some special occasions, such as the demand for small batch customization, or the need for special shapes or materials of diamond segment, etc. With the development of welding technology and mechanization, the troubles of manual welding are infinitely magnified. The first thing to bear the brunt is that the process of manual welding diamond segment requires experienced technicians. They need to master key technologies such as the characteristics of diamond, the properties of solder, the control of welding temperature and welding time, in order to ensure the welding quality and stability. In addition, the process of the manual welding diamond segment is relatively cumbersome, the production efficiency is low, and it cannot meet the large-scale and high-volume production requirements. Then the automatic welding machine came into being. There are two types of automatic welding machines, one is automatic welding machine and the other is semi-automatic welding machine. This article mainly introduces the advantages and disadvantages of semi-automatic welding machine.

With the development of welding technology and mechanization, the troubles of manual welding are infinitely magnified. The first thing to bear the brunt is that the process of manual welding diamond segment requires experienced technicians. They need to master key technologies such as the characteristics of diamond, the properties of solder, the control of welding temperature and welding time, in order to ensure the welding quality and stability. In addition, the process of the manual welding diamond segment is relatively cumbersome, the production efficiency is low, and it cannot meet the large-scale and high-volume production requirements. Then the automatic welding machine came into being. There are two types of automatic welding machines, one is automatic welding machine and the other is semi-automatic welding machine. This article mainly introduces the advantages and disadvantages of semi-automatic welding machine.

Semi-automatic welding machine is a kind of equipment commonly used for welding metal products, including welding diamond segment. The following are the advantages and disadvantages of semi-automatic welding machine welding diamond segment:

Advantages:

High production efficiency: The semi-automatic welding machine adopts automation technology, and the welding speed is fast, which can greatly improve production efficiency.

Good welding quality: the semi-automatic welding machine adopts sophisticated welding technology, which can ensure the quality and stability during welding segment , and reduce welding defects and quality problems.

Simple operation: the semi-automatic welding machine is easy to use. The operator only needs to put the workpiece into the equipment and start the welding machine to complete the whole welding process, which reduces the difficulty and technical requirements of manual operation.

Wide applicability: the semi-automatic welding machine can be applied to various types of welding segment and can meet different production needs.

Disadvantages:

High initial investment: the price of semi-automatic welding machine equipment is relatively high and requires a certain amount of investment.

High maintenance costs: semi-automatic welding machines require regular maintenance, which will increase equipment operating costs.

inability to handle large workpieces: due to the limited welding range of the semi-automatic welding machine, it cannot handle large workpieces, which will limit its application range.

Requirement of professional operator: although the operation of the semi-automatic welding machine is relatively simple, it requires certain professional knowledge and technology, as well as certain operation and maintenance skills. To sum up, the semi-automatic welding machine has the advantages of high efficiency, high quality, simple operation and wide applicability, but there are also disadvantages such as high investment, high maintenance costs, inability to handle large workpieces, and the need for professional operator.

To sum up, the semi-automatic welding machine has the advantages of high efficiency, high quality, simple operation and wide applicability, but there are also disadvantages such as high investment, high maintenance costs, inability to handle large workpieces, and the need for professional operator.

Advantages and disadvantages of semi-automatic welding machine welding diamond segment

Publish date:2023-03-13 09:23:30 Article From:Linsing diamond tools Clicks: