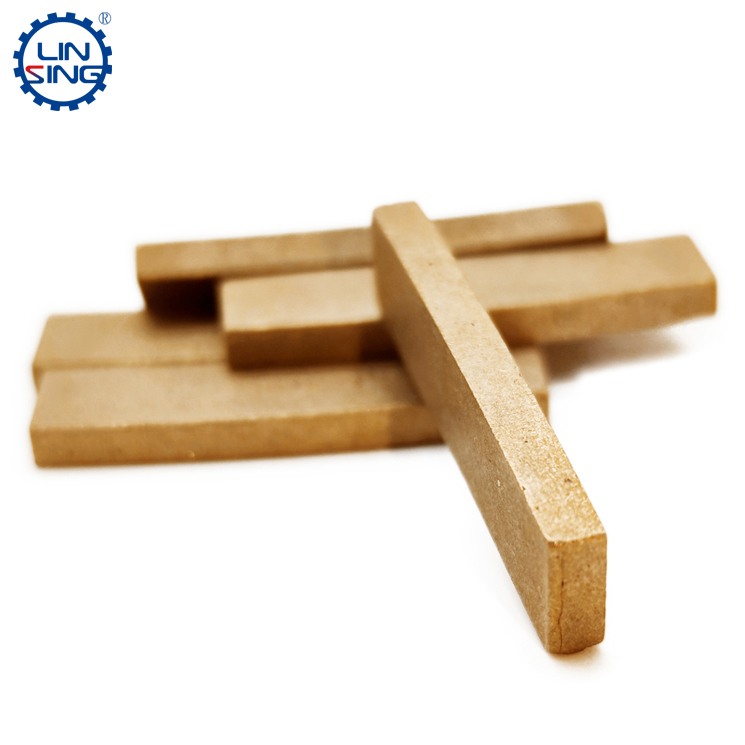

In the process of making diamond segments, it has undergone weighing, batching, cold pressing, sintering and other processes. In these processing processes, one carelessness will cause the segment to have large quality problems. According to Lin Xing diamond segments experience in the production process, the following points should be paid attention to:

1: The influence of weight

1) After the materials are weighed separately, the whole material needs to be weighed, so as to check according to the total weight of different materials.

2) After the cold pressing of the segment is completed, the segment shall be weighed, and the segment with a weight error of more than 2% shall be re-pulverized and subjected to a second cold pressing.

3) The segments that are cooled after hot pressing and sintering need to be weighed, and the segments with too much weight change are discarded.

2: The influence of size

1) After the segment is sintered, use a vernier caliper to measure the segment size, and the general error does not exceed 1%.

2) The size of the diamond bit is closely related to the time of uses of graphite mold. Generally, Linxing’s molds are used no more than 6 times to ensure the accuracy of the bit size.

3) After the segment is sintered, there are sintered body residues or slight uneven particles, which need to be reshaped later to ensure the accurate size of the segment.

4: The influence of time

1) During the sintering process, the holding time of the segment is generally 1 to 3 minutes.

2) After the heat preservation and pressure holding process is completed, first reduce the temperature and then lower the pressure to ensure that the pressure holding time is longer than the holding time.

3) The heating rate of the sintering process determines the stability of the segment, so the segment sintered by a high-power sintering machine is better than a low-power sintering machine. And the room temperature is well controlled, which can make the finished segment more stable.

5: The effect of pressure

1) Pressure reduction speed: Generally, the temperature is lowered first and then the pressure is lowered, and the pressure reduction speed is often greater than the temperature reduction speed.

2) Pressurization speed: Normally pressurize evenly. When there is a low melting point metal formula, it should be pressurized in advance.

3) Maximum pressure: The pressure value is 3.0~4.5KN/cm2. For low melting point formulas, the value should be lower, and high melting point formulas can be higher.

6: The influence of temperature

1) Cooling speed: The cooling speed should be adjusted according to the formula. The sharpness of the product can be improved when the temperature drops quickly, and the wear resistance can be improved when the temperature drops slowly.

2) Mold unloading temperature: When the mold unloading temperature is high, the surface of the segment will be oxidized and affect the quality of the segment. Under normal circumstances, the unloading temperature should not be higher than 150 degrees, preferably below 100 degrees.

3) Heating speed: when the heating speed is slow, the heat transfer is even, not easy to run out, and the internal sintering is intact; when the heating speed is fast, the heat transfer is uneven and the inner sintering is uneven.

4) Maximum temperature: There is only one optimal sintering interval for product production, but for most recipes, the sintering temperature should be slightly higher.

5) Room temperature is also an important factor affecting the stability of the segment. Good room temperature control can greatly improve the quality of the diamond segment.

In general, during the production process of diamond segments need to pay attention to the weight, size, time, pressure, temperature and many other matters, and strictly control them before they can be made into high-quality diamond tool products.