Mold damage: due to the high pressure used in the production process of the diamond segment, the mold may be damaged during use, and the surface of the mold may be damaged or deformed, which will make it difficult to remove the mold and reduce the quality of the product and its lifespan. Of course, excessive wear on the mold surface, improper maintenance of the mold, loose contact between the mold and the mold base, or unreasonable mold design itself will cause mold damage. The solution is to replace the new mold. Short mold life: The production of diamond segments requires the use of wear-resistant and corrosion-resistant materials, but even so, the mold will wear or corrode after a certain number of uses, resulting in a decline in product quality and production efficiency.

Short mold life: The production of diamond segments requires the use of wear-resistant and corrosion-resistant materials, but even so, the mold will wear or corrode after a certain number of uses, resulting in a decline in product quality and production efficiency.

Solution:

1: Use high-quality mold materials; The quality of mold materials has a great influence on the service life of the mold, so high-quality mold materials should be used.

2: Reasonable mold design; Reasonable mold design can reduce problems such as stress concentration, fatigue damage and deformation, thereby prolonging the service life of the mold.

3: Regular inspection and maintenance; Regular inspection and maintenance of the mold can detect problems and repair them in time to avoid further damage and prolong the service life of the mold.

4: Use the correct processing technology; When using the mold for processing, you should use the correct processing technology, such as maintaining an appropriate processing temperature, avoiding excessive cooling, etc., to avoid damage to the mold due to excessive processing.

5: Preheat treatment before processing; Before processing, the mold can be preheated to avoid deformation and damage of the mold due to excessive temperature changes.

6: Learn the correct use method; When using the mold, you should learn the correct use method, such as mastering the appropriate processing speed and strength, to avoid damage to the mold due to improper operation.

7: Regularly replace the mold; After a certain period of use, the mold may be damaged or worn. At this time, the mold should be replaced in time to avoid problems such as product quality decline and output reduction due to the use of aging molds. In order to avoid the above problems, it is necessary to strictly control the production conditions, mold quality and production process in the production of diamond segments to ensure the smooth progress of the demoulding process and produce more high-quality diamond segments.

In order to avoid the above problems, it is necessary to strictly control the production conditions, mold quality and production process in the production of diamond segments to ensure the smooth progress of the demoulding process and produce more high-quality diamond segments.

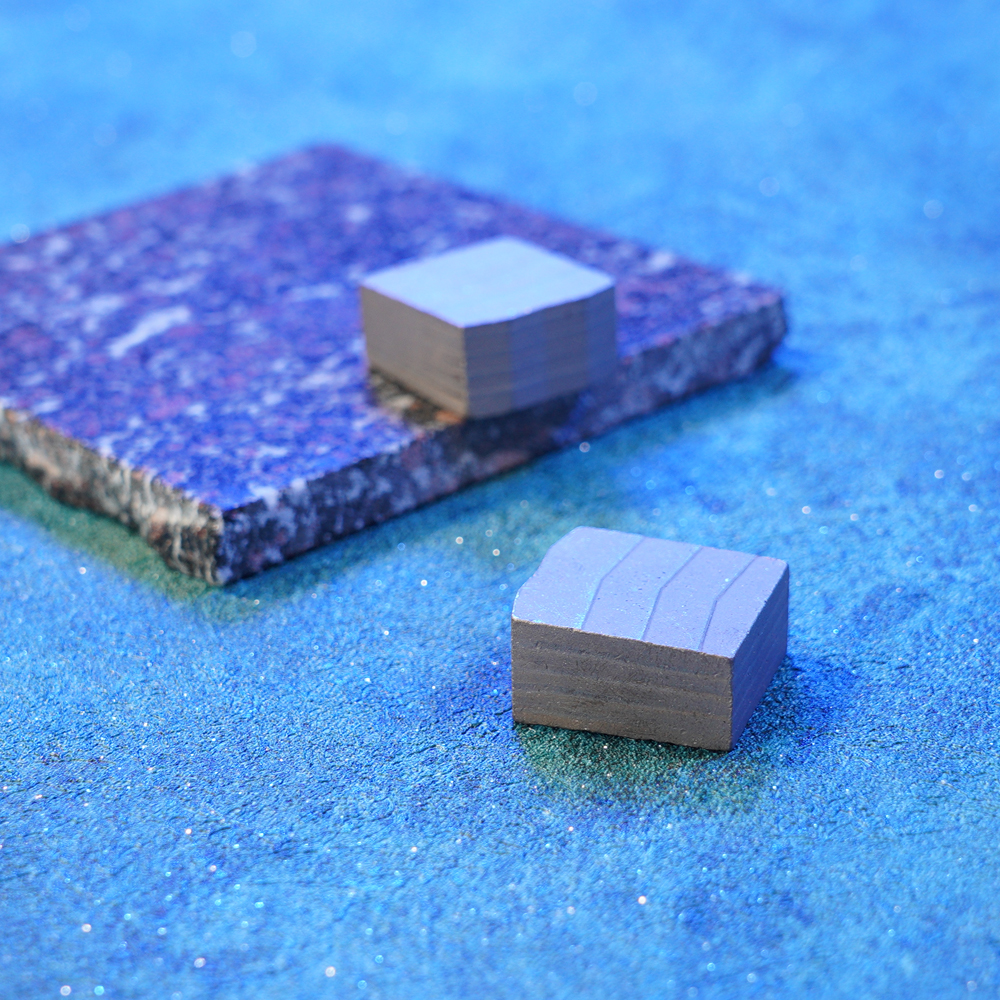

Problems encountered in the process of demoulding during diamond segment production and solutions

Publish date:2023-03-13 09:46:14 Article From:Linsing diamond tools Clicks: