The transition layer of the diamond segment refers to a layer of material between the blank blade and the diamond layer on the diamond segment. It mainly plays the role of connecting the blank blade and the diamond layer of the segment, and can also buffer the stress between the substrate and the diamond layer, reducing the possibility of the diamond segment breaking. The transition layer is usually a metal or alloy material, such as cobalt, nickel, iron, chromium, etc., and is often attached to the substrate by electroplating or spraying. The performance and quality of the transition layer have an important impact on the service life and cutting efficiency of the diamond segment. If the material of the transition layer is improperly selected or the quality is not good, it may lead to insufficient adhesion between the diamond layer and the blank blade, making the diamond segment prone to falling off, peeling off or breaking. Therefore, in the process of preparing the diamond segment, the material and thickness of the transition layer need to be strictly controlled to ensure the quality and performance of the diamond segment.

The performance and quality of the transition layer have an important impact on the service life and cutting efficiency of the diamond segment. If the material of the transition layer is improperly selected or the quality is not good, it may lead to insufficient adhesion between the diamond layer and the blank blade, making the diamond segment prone to falling off, peeling off or breaking. Therefore, in the process of preparing the diamond segment, the material and thickness of the transition layer need to be strictly controlled to ensure the quality and performance of the diamond segment.

Why do diamond segments need a transition layer? The main reason why a diamond segment requires a transition layer is because there is a large difference in thermal expansion coefficient between diamond and the base material of the segment. When the diamond segment is in use, due to the influence of high temperature and high pressure, the diamond and the substrate will have different degrees of thermal expansion, and this difference in thermal expansion may cause damage and rupture of the diamond segment.

The existence of the transition layer can alleviate the impact of this difference, and gradually smooth the difference in thermal expansion between the diamond and the blank blade, thereby reducing the stress on the diamond segment and improving its durability and service life. In addition, the transition layer can also improve the bonding strength and adhesion of the diamond segment, ensure a firm bond between the diamond particles and the blank blade, and prevent the diamond segment from falling off and being damaged.

So how to adjust the transition layer of diamond segment?

The transition layer of the diamond segment is generally prepared by metal powder and fired ceramic powder. The selection of the formula needs to consider many factors, including the type, particle size, shape of the metal powder, the type, content, and processing technology of the ceramic powder. Below are some examples of formulations for common diamond segment transition layers:

Metal Ni powder + Al2O3 ceramic powder, the mass ratio is 1:1.

Metal Co powder + Al2O3 ceramic powder, the mass ratio is 1:2.

Metal Fe powder + SiC ceramic powder, the mass ratio is 1:3.

Metal Cu powder + ZrO2 ceramic powder, the mass ratio is 2:1.

Metal Ti powder + TiC ceramic powder, the mass ratio is 1:1.

It should be noted that the specific formula needs to be selected and adjusted according to different application scenarios to obtain the best performance and life of the diamond segment. In addition, the preparation process of the transition layer also needs to control the firing temperature, time, atmosphere and other parameters to ensure good adhesion and matching with the diamond layer and the metal powers.

Finally, let me talk about why ceramic powder is used in the transition layer of the diamond segment?

The transition layer of the diamond segment needs to use ceramic powder, mainly because the ceramic powder has good adhesion and plasticity, which can be well combined with the diamond powder and the metal substrate, thereby enhancing the bonding force between the diamond and the metal substrate And compactness, improve the strength and wear resistance of the whole diamond segment. In addition, ceramic powder can also be used as a filling material to fill the gaps between diamond particles, thereby increasing the density and hardness of the diamond segment. In general, the transition layer of the diamond segment is mainly used to better connect the diamond segment and the blank blade, and at the same time, it is necessary to take into account the prevention of large-area and large-scale thermal expansion effects of the saw blade.

In general, the transition layer of the diamond segment is mainly used to better connect the diamond segment and the blank blade, and at the same time, it is necessary to take into account the prevention of large-area and large-scale thermal expansion effects of the saw blade.

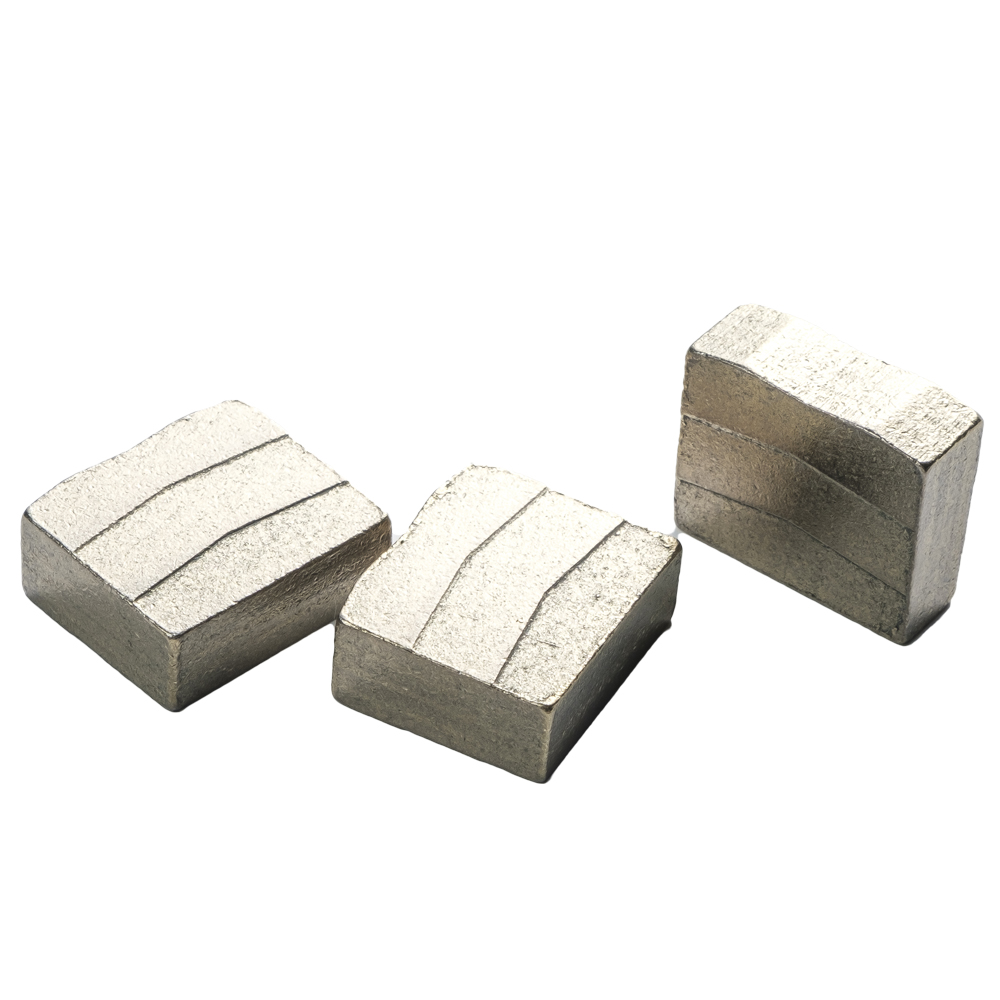

Diamond segment transition layer

Publish date:2023-05-09 11:39:21 Article From:Linsing diamond tools Clicks: