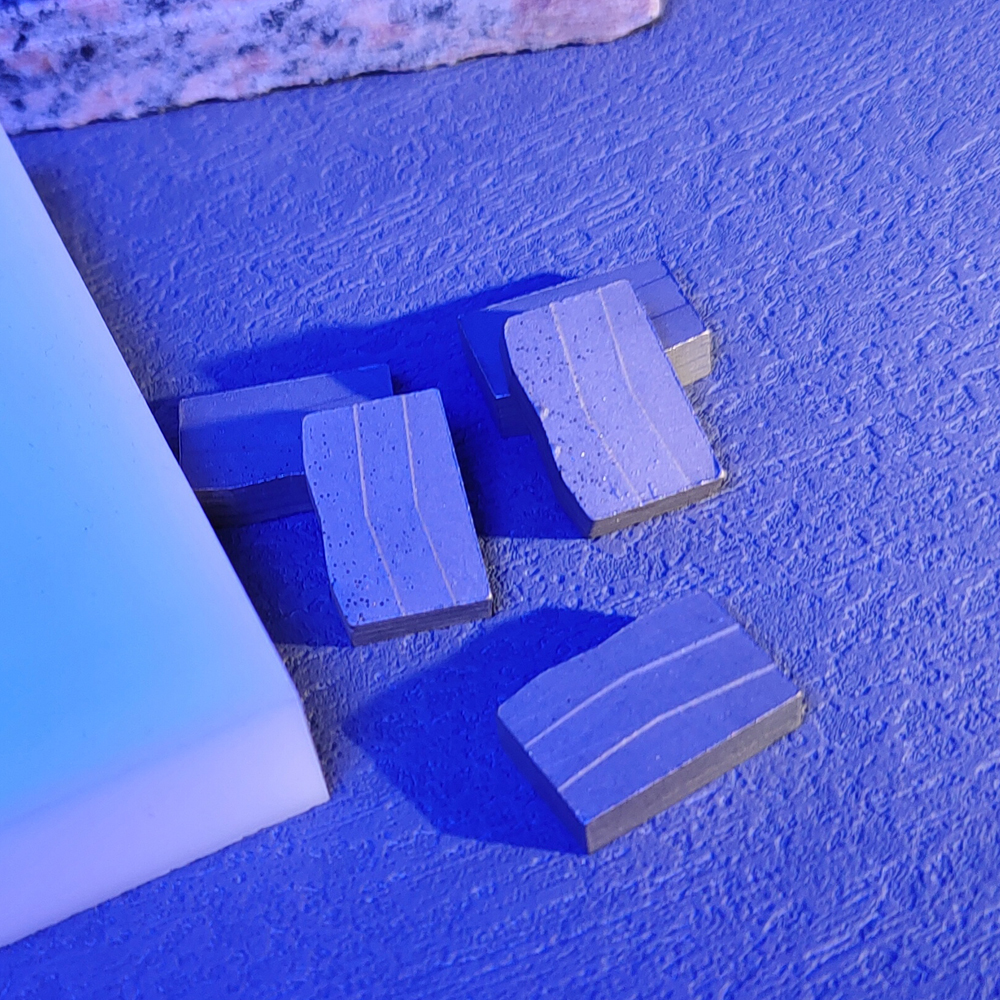

What is the granite segment? Granite segment is a kind of diamond segment specially used for cutting granite, which is usually made of a mixture of diamond particles and metal powder. Granite is a hard and durable rock that requires high-quality segments to cut effectively. Granite segments usually have the characteristics of high density, high hardness, high strength and wear resistance, which can provide excellent results and long life when cutting granite. Granite segment has the following characteristics:

Granite segment has the following characteristics:

1: High blade hardness: Granite is a very hard stone. To cut it, you need to use a high-hardness blade. The granite segment is a blade specially used for cutting granite.

2: Good wear resistance: The surface of the granite segment has been specially treated to enhance its wear resistance and keep it sharp when cutting granite.

3: High cutting efficiency: The granite segment adopts special diamond formula and blade structure design, which can improve cutting efficiency and reduce waste when cutting granite.

4: The quality of the blade is stable: The production process of the granite segment is very demanding. It is made of high-quality raw materials and precision processing technology, which can ensure the quality of the segment is stable and the cutting effect is consistent.

5: Wide range of application: The granite segment is not only suitable for cutting granite, but also can be used for cutting other hard stones, such as marble, quartz, etc.

In a word, the granite segment is a high-hardness, wear-resistant, high-efficiency blade specially designed for cutting granite, with stable quality and wide application range. But the life of granite segment is affected by many factors:

The life of a granite segment is affected by many factors, such as the quality of the diamond segment, cutting conditions, hardness and structure of the granite stone, etc. Generally speaking, high-quality granite segments can have a longer life under proper use conditions, while low-quality segments are easily damaged and have a shorter life. At the same time, if the cutting conditions are not suitable, such as too fast cutting speed, insufficient cutting water, etc., it will also have a negative impact on the life of the segment. In addition, the hardness and structure of granite stone are different, which will also affect the life of the segment. Generally speaking, the higher the hardness of the granite stone, the shorter the life of the segment; the finer the structure of the granite stone, the shorter the life of the segment. Therefore, when using a granite segment, it is necessary to select the appropriate segment and cutting conditions according to the specific situation to prolong the life of the segment.

So how to improve the life of the granite segment? To improve the life of granite segment, the following aspects can be considered:

1: Reasonable selection of the segment: Select the specification and model of the segment according to the specific cutting situation, such as the diameter and number of teeth of the segment, so as to avoid damage to the segment caused by excessive wear or excessive load.

2: Control cutting parameters: When cutting granite, the cutting speed, feed rate and other parameters should be controlled according to the specifications and hardness of the segment to avoid excessive wear or excessive load.

3: Maintenance of the segment: Clean the segment in time after use, remove the dust and debris generated during cutting, avoid corrosion to the diamond segment, and regularly lubricate and maintain the segment to prolong the service life of the segment. 4: Keep the cutting stable: When cutting granite, keep the cutting stable and avoid excessive vibration or shaking, so as to avoid excessive wear and tear on the segment.

4: Keep the cutting stable: When cutting granite, keep the cutting stable and avoid excessive vibration or shaking, so as to avoid excessive wear and tear on the segment.

5: Use proper coolant: Using proper coolant can reduce the temperature of the segment, reduce the wear and fatigue of the segment, and also help to clean the debris and dust generated during cutting.

Determinants of service life of granite diamond segment

Publish date:2023-05-09 11:32:13 Article From:Linsing diamond tools Clicks: