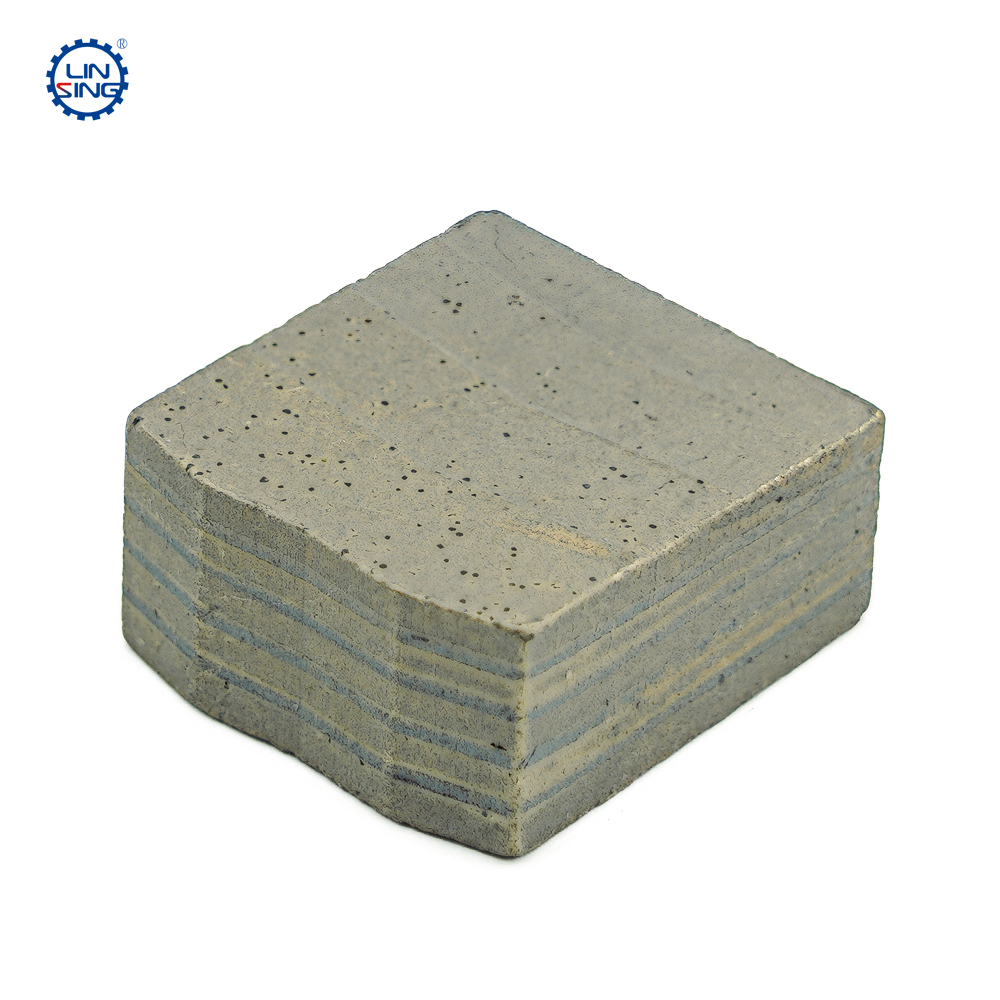

At present, the more common diamond segments are iron-based diamond segments, copper-based diamond segments and cobalt-based diamond segments. Among them, iron-based segments are used in large quantities because of their low price, good abrasiveness, and stable structure. Most of diamond segments used to cut granite and sandstone belong to this category, so they have become the most widely used segment type at present. However, the biggest problem with the iron-based segment is that the content of iron powder is too high, which will lead to an increase in the sintering temperature, and this increase in temperature will have the following disadvantages for the segment. 1. Diamond will slowly oxidize above 700 degrees Celsius, that is the process of gradual graphitization. The higher the temperature, the more obvious this phenomenon is. Such oxidation will directly lead to a decrease in the holding force and cutting performance of the diamond during the cutting process.

1. Diamond will slowly oxidize above 700 degrees Celsius, that is the process of gradual graphitization. The higher the temperature, the more obvious this phenomenon is. Such oxidation will directly lead to a decrease in the holding force and cutting performance of the diamond during the cutting process.

2. Iron can strongly erode diamond at high temperature to form Fe3C, which decomposes into graphite when the temperature is lowered, thereby increasing the hardness of the segment, and even directly causing large-scale shedding of diamond, especially the higher the temperature, the longer the sintering time , this situation will become more obvious.

3: Increasing the sintering temperature will increase the consumption of energy consumption and directly affect the production cost.

However, if the sintering temperature is directly lowered, the following undesirable situations will also occur:

1: The iron-based carcass has poor impact resistance. Due to the incomplete sintering of iron powder, quality problems will occur during use, such as poor impact resistance, which directly leads to deformation and drop of the segment.

2: The hardness of the iron-based matrix is not enough, and the sintering temperature also decreases in this case.

Therefore, forcibly lowering the temperature cannot solve the core problem of the iron-based segment, so people consider how to solve the problem by reducing the content of iron powder or changing the particle size of iron powder? But people find that iron powder is very active, especially fine-grained iron powder is easier to oxidize. At this time, due to the reduction of iron content, the performance of the diamond segment also changes; and the reduction of iron powder content will reduce the stability of the diamond segment and lose the relevant properties of the iron-based diamond segment. Finally, people found that after adding some low-melting point metals , can significantly improve the problem of high-temperature sintering of iron-based segments.

In specific implementation, through long-term testing, people have found that the following methods can be used to solve the problem: adding a small amount of low-melting point elements Sn and Zn to the matrix material, reducing the sintering temperature and holding time, and avoiding diamonds from turning into graphite. This is the first method, other metals with low melting points can also be added as needed.

The second method is to coat the diamond surface (Ti, W, Cr). These strong carbide elements are conducive to the formation of a dense layer of carbides on the diamond surface, improving the encapsulation force of the matrix material on the diamond. It also avoids the combination of iron powder and diamond, and avoids the graphitization of diamond. This method is currently the most commonly used method, but the method and method of coating are also very particular. For example, the brazing coating method is better than the aerosol method.

The third way is to add an appropriate amount of phosphorus powder to the carcass material. After phosphorus is added to the iron-based carcass, the Fe-P alloy (eutectic temperature point 940 degrees Celsius) is formed, which greatly reduces the sintering temperature of the alloy. Prevent iron from corroding diamond. In general, iron-based segments can be solved by adding some low melting point materials and protecting the diamond surface to solve the problems in the sintering process of iron-based segments. However, with the improvement of diamond segment production process and technology, lowering the sintering temperature is not the best way to solve the iron-based segment. At a reasonable temperature, reducing the unfavorable factors affecting the cutting of the diamond segment and enhancing the sawing performance is the ultimate solution to the problem.

In general, iron-based segments can be solved by adding some low melting point materials and protecting the diamond surface to solve the problems in the sintering process of iron-based segments. However, with the improvement of diamond segment production process and technology, lowering the sintering temperature is not the best way to solve the iron-based segment. At a reasonable temperature, reducing the unfavorable factors affecting the cutting of the diamond segment and enhancing the sawing performance is the ultimate solution to the problem.

What can be added to the iron-based diamond segment to reduce the sintering temperature?

Publish date:2022-12-13 11:32:44 Article From:LINSING diamond tools Clicks:

Diamond Segment For Gang Saw

Diamond Segment For Marble Cutting

Buff Fickert For Granite

PDC Cutters For Chain Saw

Diamond Sintered Engraving Bit

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS