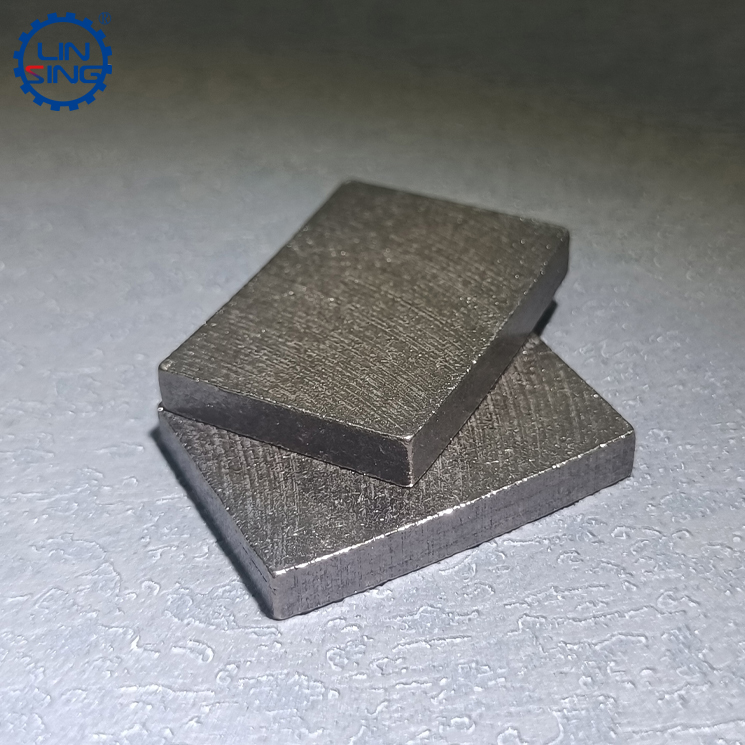

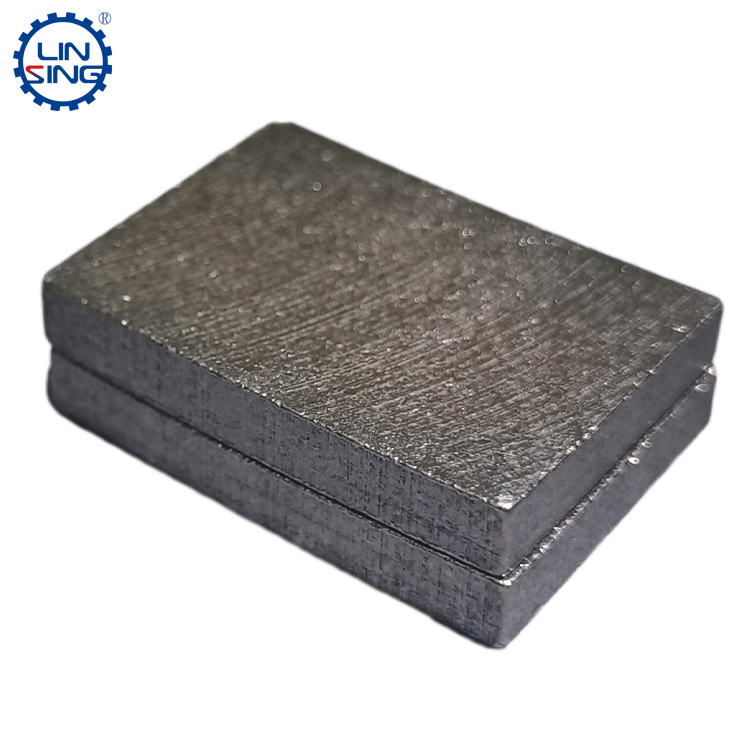

In daily life, if you have been to a hardware store, it is easy to find diamond saw blades, especially 105mm-230mm saw blades, which are often encountered in home improvement projects, and if you lay stone on the walls and floors of your home If you have been to a stone factory, you will find more sizes of stone saw blades, from cutting blocks to cutting stone slabs. The saw blade specifications range from 300-3500mm, whether it is small slices or medium and large stone cutting saws. You will find a metal diamond segment type saw tooth on the top of the saw blade. These are the diamond segment. The diamond segment is the working part of the diamond saw blade. Cutting any material is to grind the material to be cut through the segment to play the role of the cutting edge. Such a segment is made of a mixture of metal bond and diamond powder, and diamond is The part of the chip blade used for cutting, the metal bond is more to fix the diamond.

Since the role of diamond in the segment is so important, how to choose the diamond powder of the segment? Is it a higher intensity? Still need higher concentration or larger particle size? In this article, we will introduce the influence of diamond strength, concentration and particle size on sawing tools, and we will introduce the diamond raw materials commonly used in Linxing diamond tools.

1. The diamond concentration of the segment

Diamond concentration refers to the content of diamond powder in a certain volume of diamond segment, because diamond powder is the main cutting part. If the concentration of diamond powder is too low, it means that there is too little diamond, then there will be a lack of cutting core inside the segment, and the segment will not move at all. Happening. Then as the diamond concentration goes from low to high, the sharpness of the saw blade increases, and the service life gradually increases. After reaching a certain concentration, if you increase the concentration, the sharpness of the segment will gradually decrease, and the life span will gradually increase.

It can be seen that when the diamond concentration is increased, the processing efficiency is a parabolic curve, while the life is a curve that gradually increases after a rapid rise. Therefore, choosing a certain concentration between the two points where the processing efficiency and the life intersect is the best diamond segment concentration.

If the segment price remains the same and the diamond concentration is too high, you can appropriately use multiple non-working layers to reduce the production cost of the segment. At present, this solution can solve most of the segment sharpness situations, which is also Linxing diamond segment. Using high-concentration segments can still have high sharpness and longevity.

2. The diamond strength of the segment

The strength of diamond refers to the hardness of diamond. The strength of diamond is an important indicator of cutting performance. If the strength of diamond is not enough, then the diamond will be easily damaged during the cutting process, and it will wear very quickly, so that it does not have the normal grinding effect. , The segment products made of such diamonds are not sharp enough and their lifespan will be shorter. The over-strength diamond also has some problems. For example, this kind of diamond is not easy to be broken. During the cutting process, the particles will always scratch the incision and make the slate appear scratched. Moreover, the diamond of this strength is expensive and the bond loss is much higher. The degree of diamond consumption, a large amount of diamonds fall off due to the consumption of the bond, resulting in a waste of diamonds. Therefore, Linxing chooses a diamond with a strength of 130-140N, which is neither too hard nor too soft, and is suitable for cutting most of the stones at home and abroad.

3. Segment diamond size

Diamond particle size is firstly manifested in the mixed particle size and the same particle size. The mixed particle size, diamond segment has high durability, and different particle sizes play different roles. However, because the particle size distribution is too random, segment instability is prone to occur, such as The segment efficiency is very high, and some segments are extremely inefficient. These are all caused by the mixed use of diamond particle size. And if the same particle size is used, the segment is very sharp, but such a segment has a general impact resistance. Once it encounters a hard stone, it is easy to fail to cut, and even the segment is worn out too quickly.

The particle size is also the consideration of size. Large particle size has stronger impact resistance, but requires higher segment structure. At present, the size of large particles is generally adopted by Korean manufacturers. Chinese manufacturers all use small and medium-sized diamond particle sizes. Such small particles have higher efficiency, better breaking capacity, and are more suitable for more versatile segments.

Linxing uses diamond with a 50/60 mesh size as the main material for the segment. The segments currently produced have been recognized by customers in terms of quality and stability.

Selection of diamond powder in segment

Publish date:2022-07-06 19:34:57 Article From:Linsing Diamond Tools Clicks:

Related News

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- Why does the diamond segment not cut the stone? Over-carbonization is one of the reasons

- How to choose diamond powder for diamond segment

- How to calculate the content of diamond in the diamond segment

- Diamond segment powder