Diamond segment sintering is the process of sintering diamond particles into a whole through high temperature and high pressure, making it a hard and wear-resistant segment material. During the sintering process, the diamond particles are heated to close to the melting point, while the metal powder is melted and filled in the gap between the particles. After the temperature cools down, the diamond particles and the metal powder are combined to form a diamond segment. Commonly used sintered metals are cobalt, nickel, iron, tungsten, etc. The level of sintering temperature and pressure, as well as the type and content of metal powder will affect the hardness and strength of the diamond segment after sintering. The specific sintering process is as follows:

The specific sintering process is as follows:

Mixing of ingredients: Mix diamond powder and metal powder in a certain proportion, and add an appropriate amount of binder to make a uniform mixture.

Compression molding: The mixture is placed in a compression mold and pressurized to form it. Cold pressing is usually used, that is, high pressure is applied at room temperature to form it.

Sintering: Put the formed body into a sintering furnace and sinter under high temperature and high pressure conditions. The sintering temperature is usually between 700°C and 900°C, and the pressure is between 50-70MPa. During the sintering process, the metal powder gradually melts and infiltrates between the diamond particles, forming a metal bond and a bond between the diamond particles.

Cooling treatment: After the sintering is completed, the green body is taken out from the sintering furnace for cooling treatment.

Subsequent processing: The cooled green body is processed, including cutting, grinding, grinding and other processes, and finally made into a diamond segment. What is the principle of diamond segment sintering?

What is the principle of diamond segment sintering?

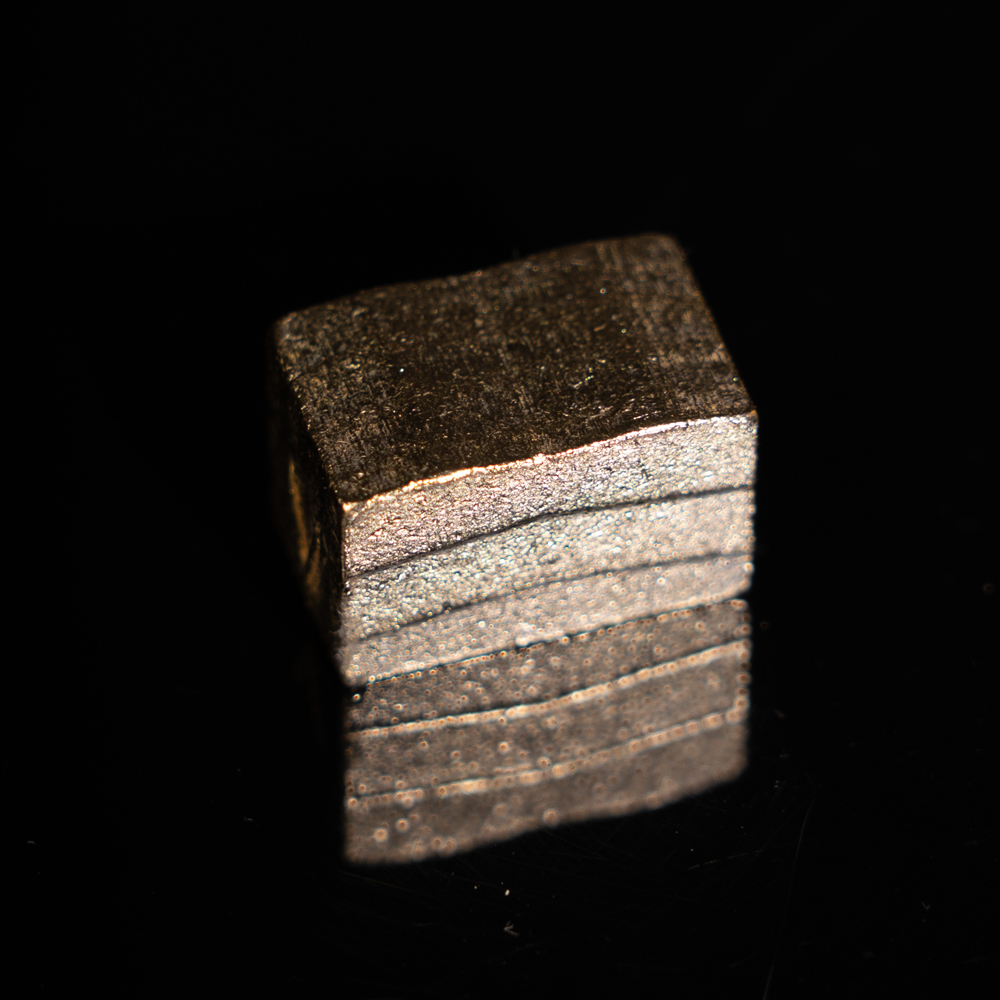

During the sintering process of the diamond segment, the diamond powder undergoes a process of recrystallization and grain growth under the action of sintering, and the processes of interdiffusion, recrystallization and interparticle bonding occur between the grains, and finally form dense diamond segment. This sintering method can not only increase the hardness and wear resistance of the diamond segment, but also make the intergranular bonding of the diamond segment stronger, improving its service life and performance.

Specifically, when diamond particles are pressed under high temperature, interatomic migration occurs between diamond particles, leading to intergranular aggregation. This process is called sintering. According to the sintering method, it can be divided into two types: liquid phase sintering and solid phase sintering.

Liquid phase sintering means that during the sintering process graphite and metal powders are added to the diamond powder to form a liquid phase. At high temperatures, the diamond particles become encapsulated by graphite and metal powders in the liquid phase, forming a jelly-like substance. Under the condition of high temperature and high pressure, this substance can make the diamond particles better bonded, thus forming a stronger diamond segment.

Solid-phase sintering means that during the sintering process, graphite and metal powder are not added, but the interatomic migration between diamond particles is directly used to make them bond. Under the conditions of high temperature and high pressure, some new bonds will be formed between the diamond particles, which will make the bonds between the particles stronger. Solid phase sintering generally requires higher temperatures and higher pressures, but produces higher quality diamond segment.

Whether it is liquid phase sintering or solid phase sintering, the temperature and pressure need to be controlled during the sintering process to ensure that the aggregation and bonding between diamond particles are optimal.

Sintering principle of diamond segment

Publish date:2023-05-08 22:05:34 Article From:Linsing diamond tools Clicks: